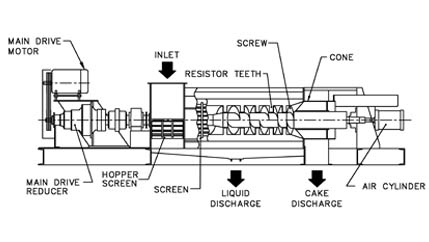

The Twin Screw Press is a machine in which two screws of progressively reducing pitch rotate inside a screen surface. Material entering the hopper is subjected to gradually increasing pressure as it moves toward the exit end of the press, forcing the liquid phase to extrude through the screen. High capacity continuous dewatering is possible with slippery materials such as spent grain, fruits and vegetables, citrus waste, fish, sugar beet pulp, and shrimp waste.

Dewatering of chitin and chitosan has proven to be an excellent application because of the positive feeding characteristic of the press.

With corn silage (husk and cob) from a sweet corn cannery, the shredder (chopper) is no longer necessary.

All Twin Screw Presses require a variable speed drive (VFD), because the capacity of these presses is very sensitive to changes in speed.

Outstanding Characteristics of the Twin Screw Press include very positive feeding, low horsepower, and automatic adjustment for changes in feed rate to the press. Seven stages of compression in overlapping screws result in very strong dewatering and feeding action. A discharge cone actuated by air cylinders allows consistent performance over a wide range of flow rates and consistencies. Slicing action of the interrupted flight screws results in reduced power consumption. See US Patent 6,550,376 on our web site.

| Model | Maximum Inbound Capacity* TON/HR |

Typical Screw RPM |

Screw Horsepower |

Length Feet |

Width Feet |

Height Feet |

Weight Lbs |

| TSP-6 | 1-2 | 30 | 5-10 | 10 | 2 | 2.5 | 2,400 |

| TSP-10 | 5-10 | 20 | 10-20 | 15.5 | 3 | 3 | 5,200 |

| TSP-12 | 10-20 | 16 | 20-30 | 18 | 3.5 | 4 | 8,800 |

| TSP-16 | 15-35 | 13 | 40-60 | 19.5 | 6.7 | 5 | 28,000 |

| TSP-24 | 40-80 | 9 | 75-150 | 23 | 8 | 6 | 45,000 |

* Subject to on-site testing