Home » Standard General Service Screw Presses (older brochure)

Home »

Home » Standard General Service Screw Presses (older brochure)

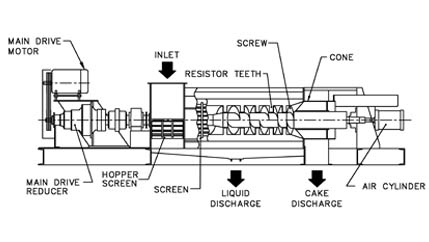

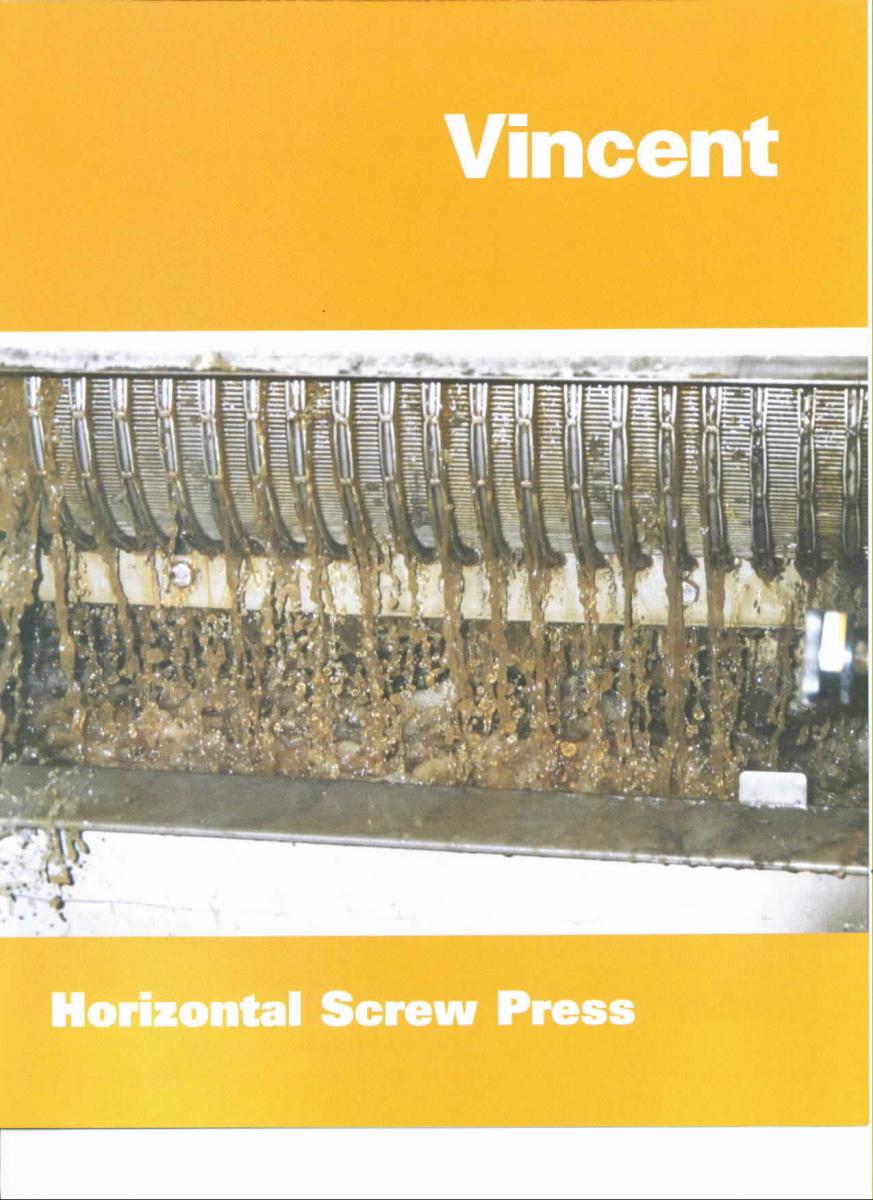

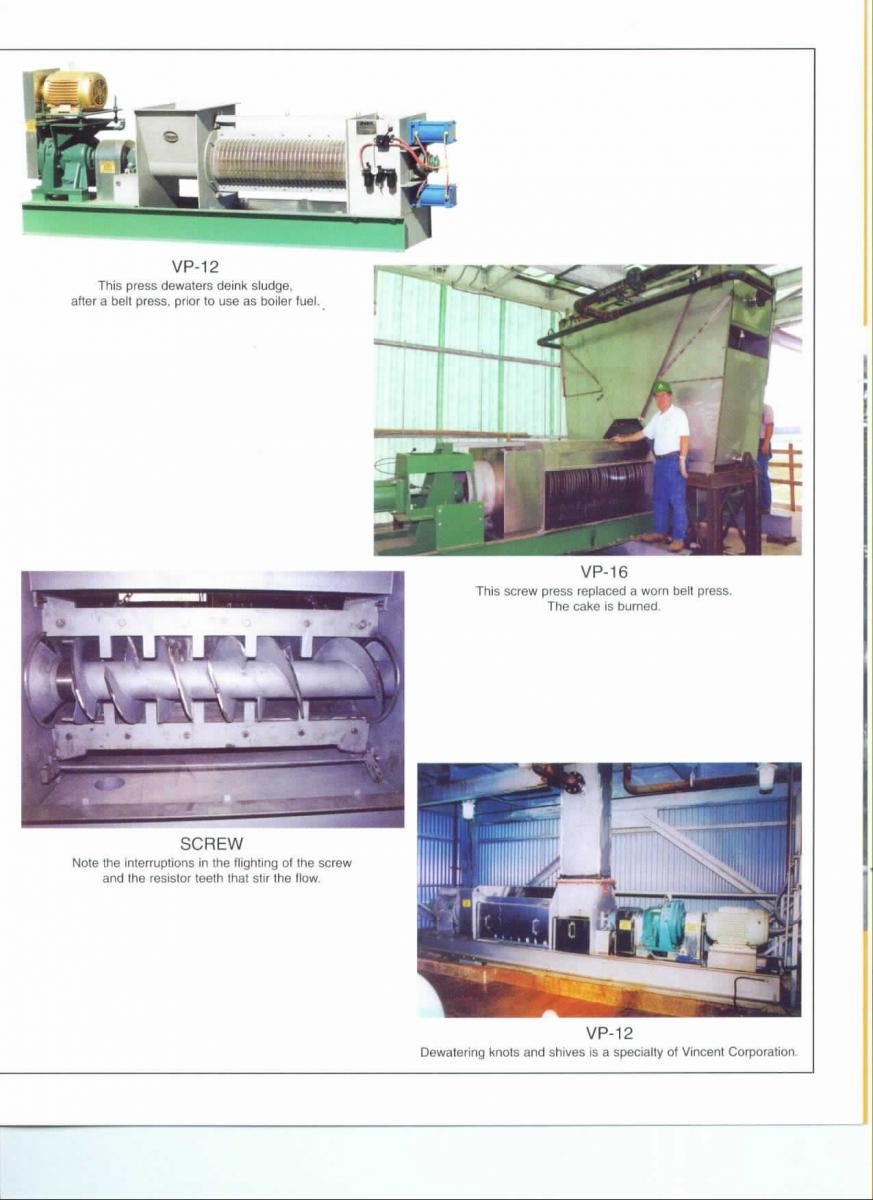

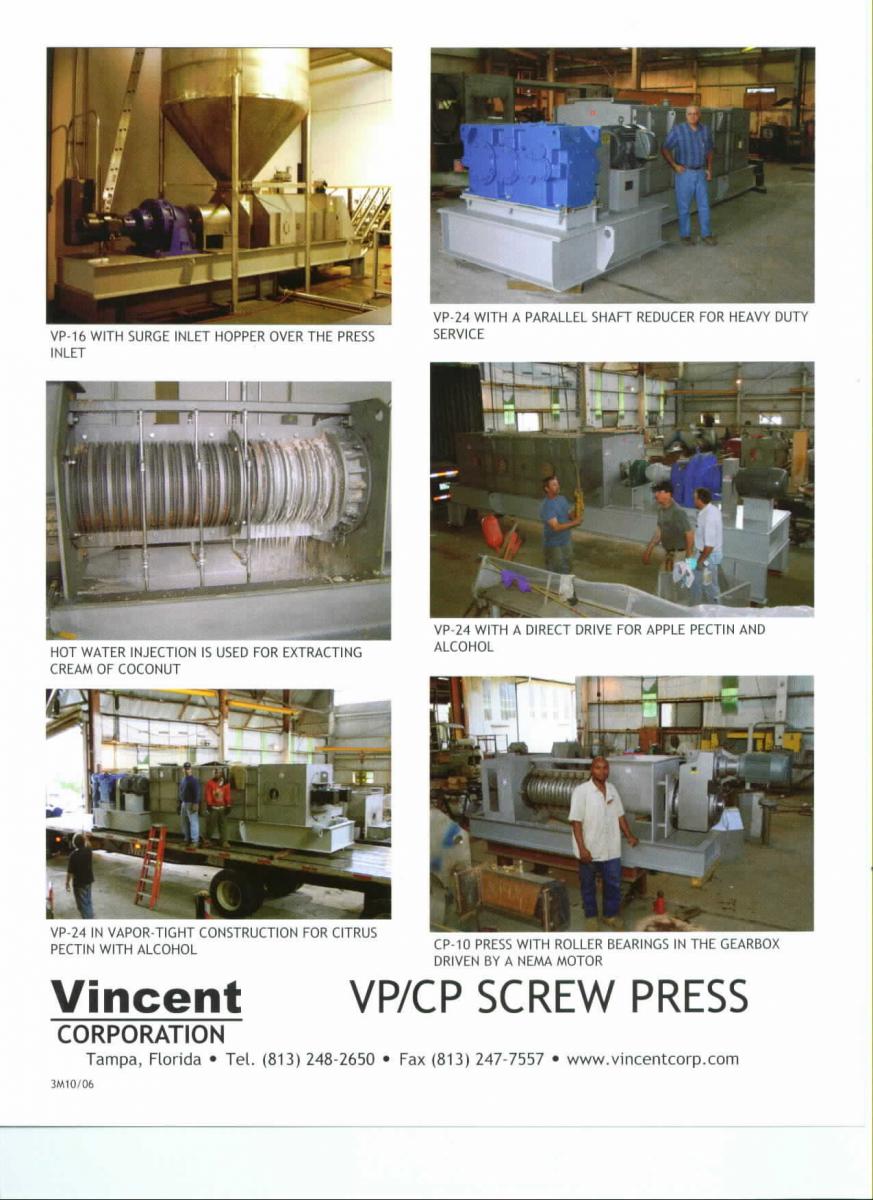

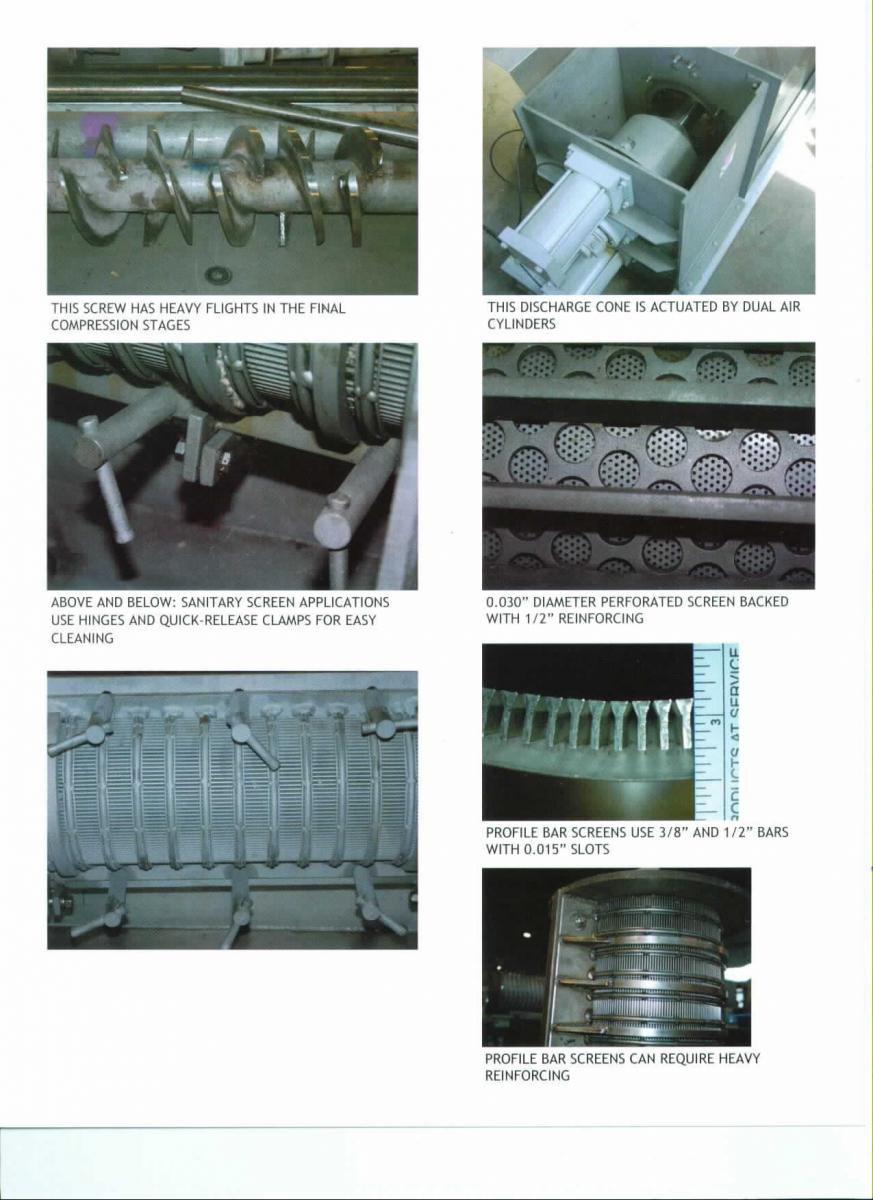

The Vincent Screw Press is a continuous dewatering press, semi-custom engineered for your application. It has a graduated pitch, interrupted flight screw. The screw rotates inside a screen, forcing liquid through this screen. The Vincent Press handles materials often considered unpressable, has low operating and maintenance costs, and is easy to clean. Press cake moisture is controlled by a discharge cone, actuated by an air cylinder. This provides easy adjustment of the dewatering. Options include both perforated and profile bar (slotted) screens, a rotating cone, hard surfacing on the screw, and screen in the inlet hopper and on the face of the cone. Standard construction is stainless steel, with a carbon steel bed frame on the larger machines.

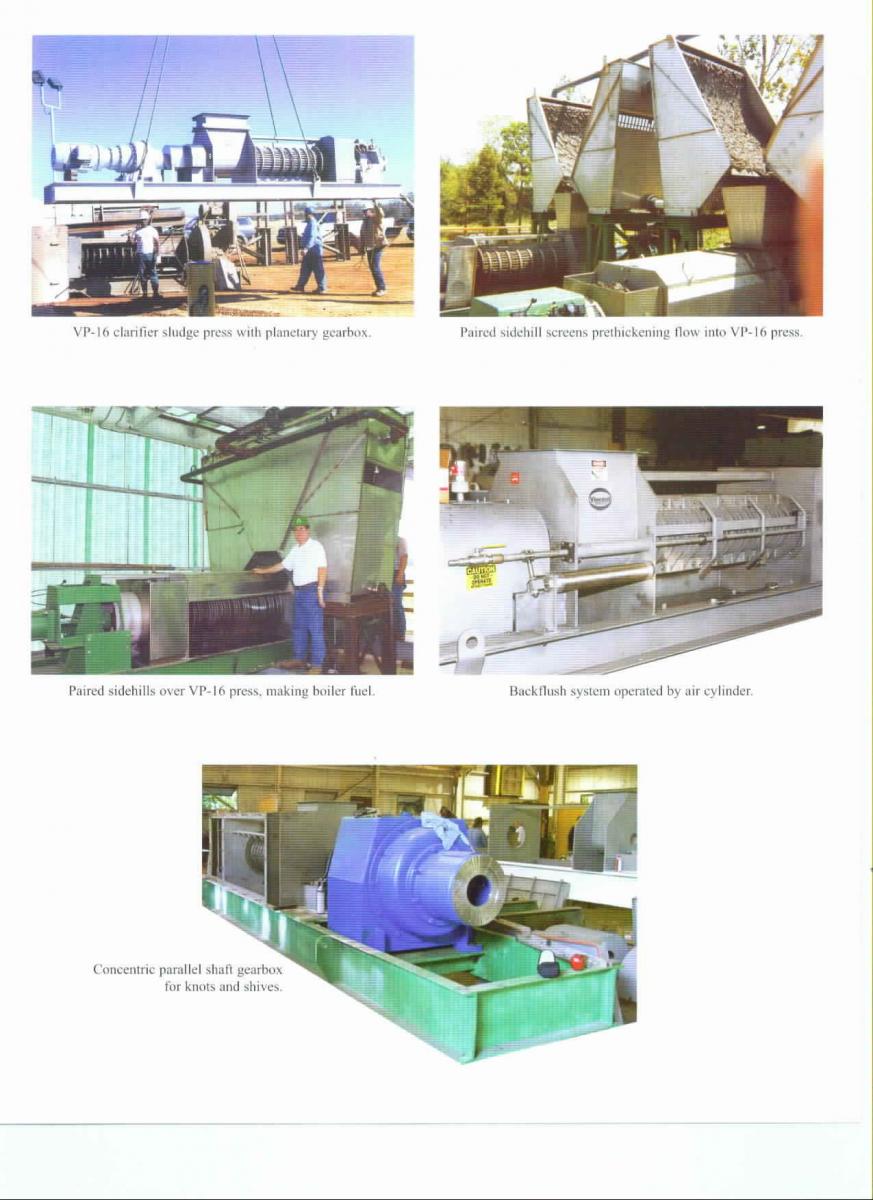

The Series VP presses use a foot mounted gearbox, while the Series CP’s use a hollow-shaft gearbox. All gearboxes are rated for Class II service.

Dilute materials can be pumped directly into the screw press. Sometimes pre-thickening improves performance, typically with a static screen.

Because of the screw design, with interrupted flights, these presses typically operate at constant speed. No variable speed drive (VFD) is required.

Many applications for these presses involve waste dewatering. They are used on pulp & paper mill rejects, citrus peel, fiberglass insulation, cooker crumb (French fries and McNuggets), tobacco, and spent coffee grounds.

Food-grade juicing applications include pineapple, cranberries, coconut, apples, grapes, alfalfa, and many nutraceuticals.

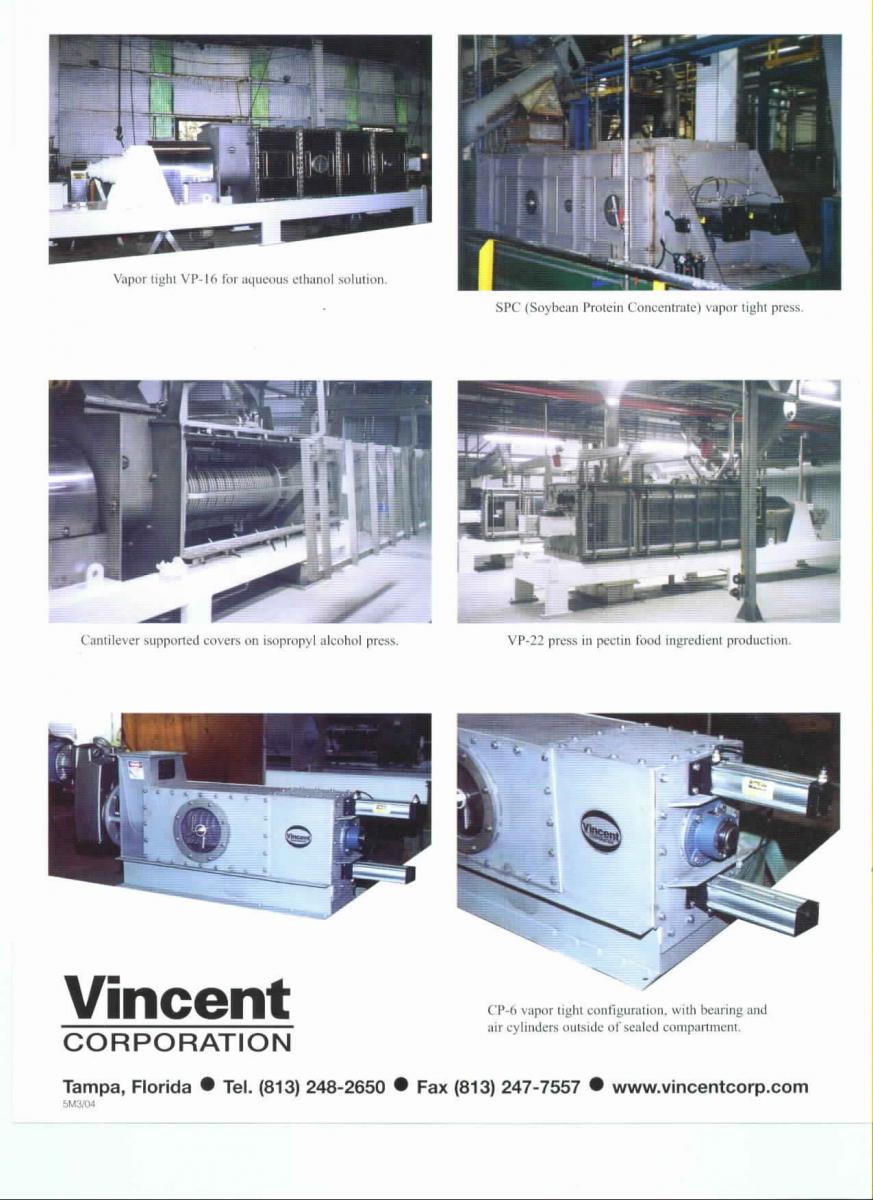

Vapor-tight presses are a specialty. These are used in the production of SPC (soybean protein concentrate), citrus and apple pectin, Xanthan gum, and bioresin.

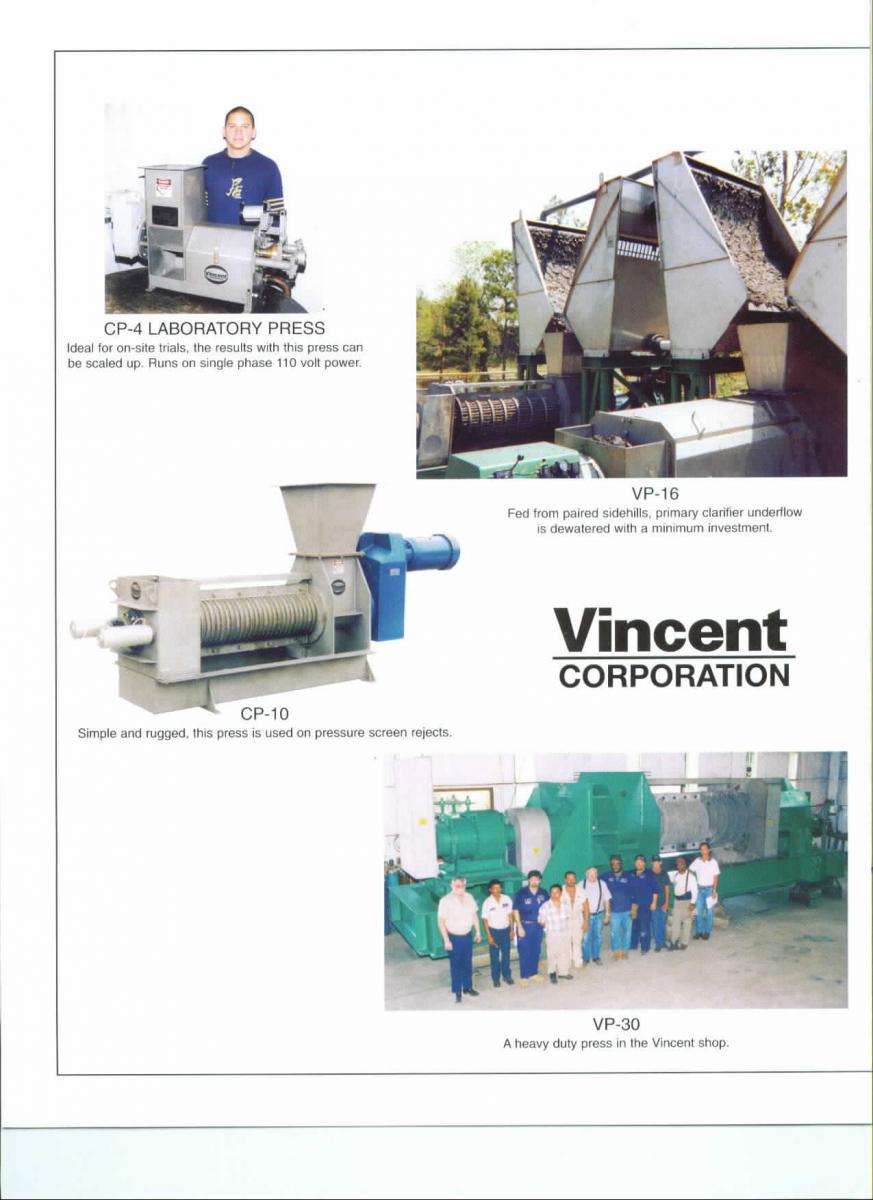

Laboratory and pilot plant models are popular.

Vincent maintains a very large fleet of rental presses. These are available for on-site testing and demonstration. Samples are run at our Tampa Works at no charge.

| Model | Maximum Capacity* lb/hr(inbound) |

Typical Screw RPM |

Motor Horsepower |

Length Feet |

Width Feet |

Height Feet |

Weight Lbs |

| CP-4 | 800 | 12-30 | 1-1/2 | 4 | 1.2 | 2 | 350 |

| CP-6 | 2,500 | 15-30 | 2-5 | 7.5 | 1.5 | 2.5 | 900 |

| CP-10 | 8,000 | 17-25 | 5-15 | 11 | 2 | 3 | 4,200 |

| CP-12 | 18,000 | 12-20 | 7.5-20 | 13 | 2.5 | 4 | 7,600 |

| VP-16 | 36,000 | 10-15 | 20-30 | 20 | 3.5 | 5 | 12,000 |

| VP-22 | 70,000 | 6-12 | 40-75 | 23 | 4.5 | 5.5 | 28,000 |

| VP-30 | 110,000 | 5-10 | 100-150 | 26 | 8 | 7 | 62,000 |

|

|

|

|

|

|

|