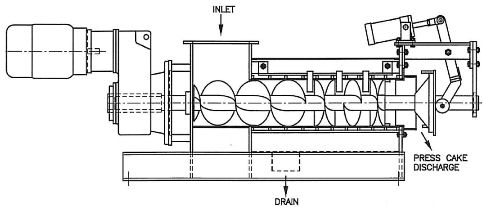

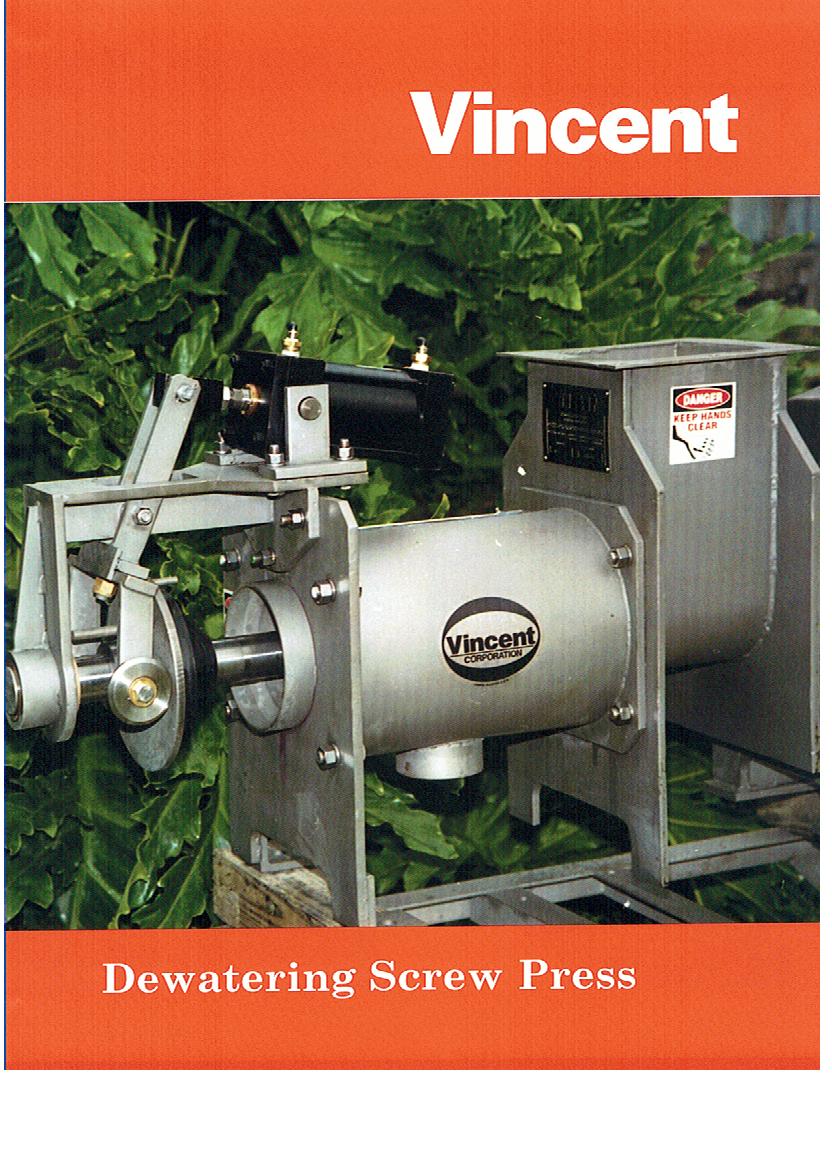

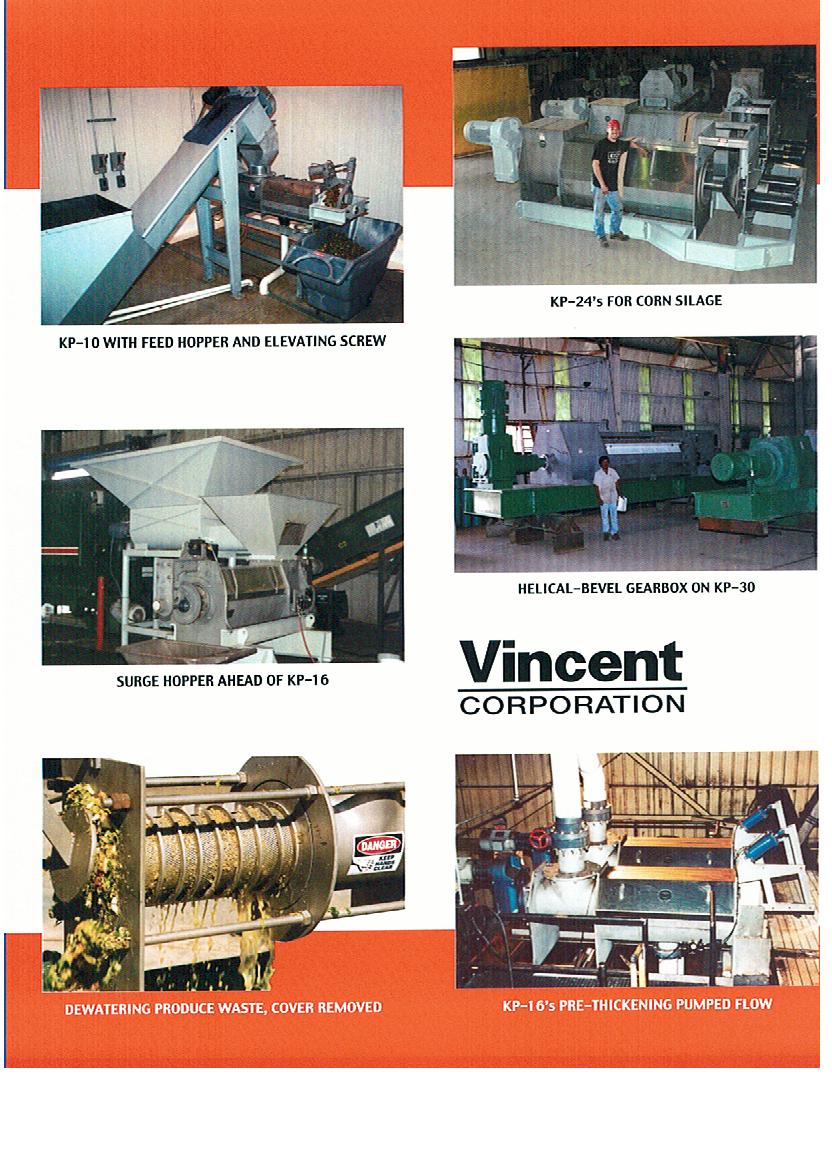

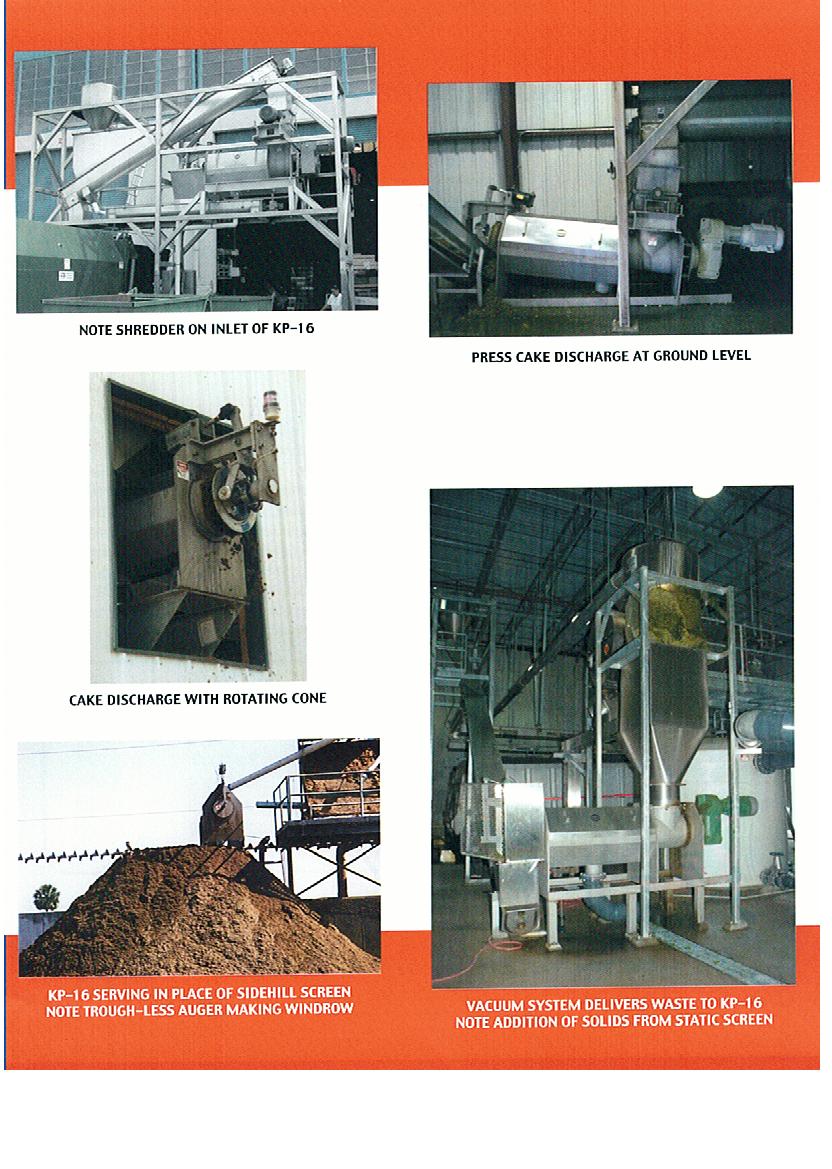

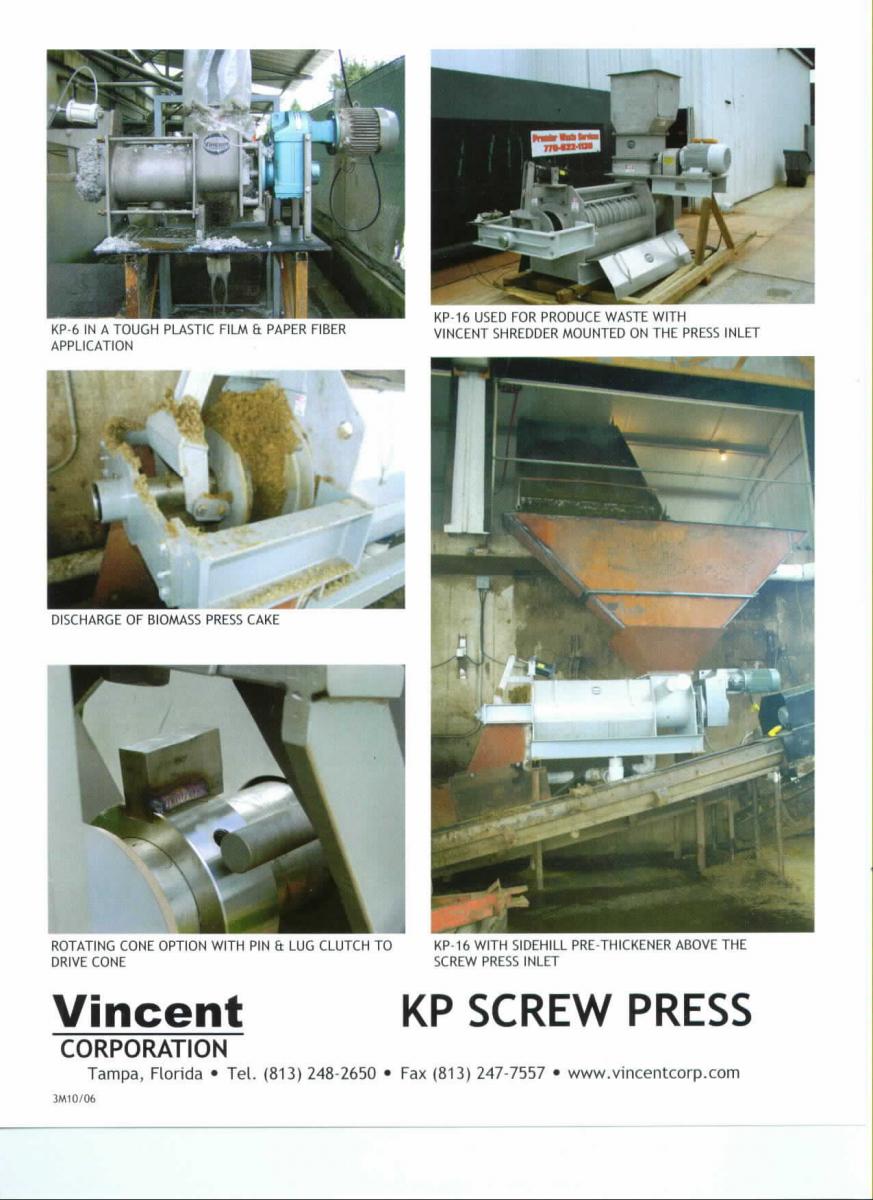

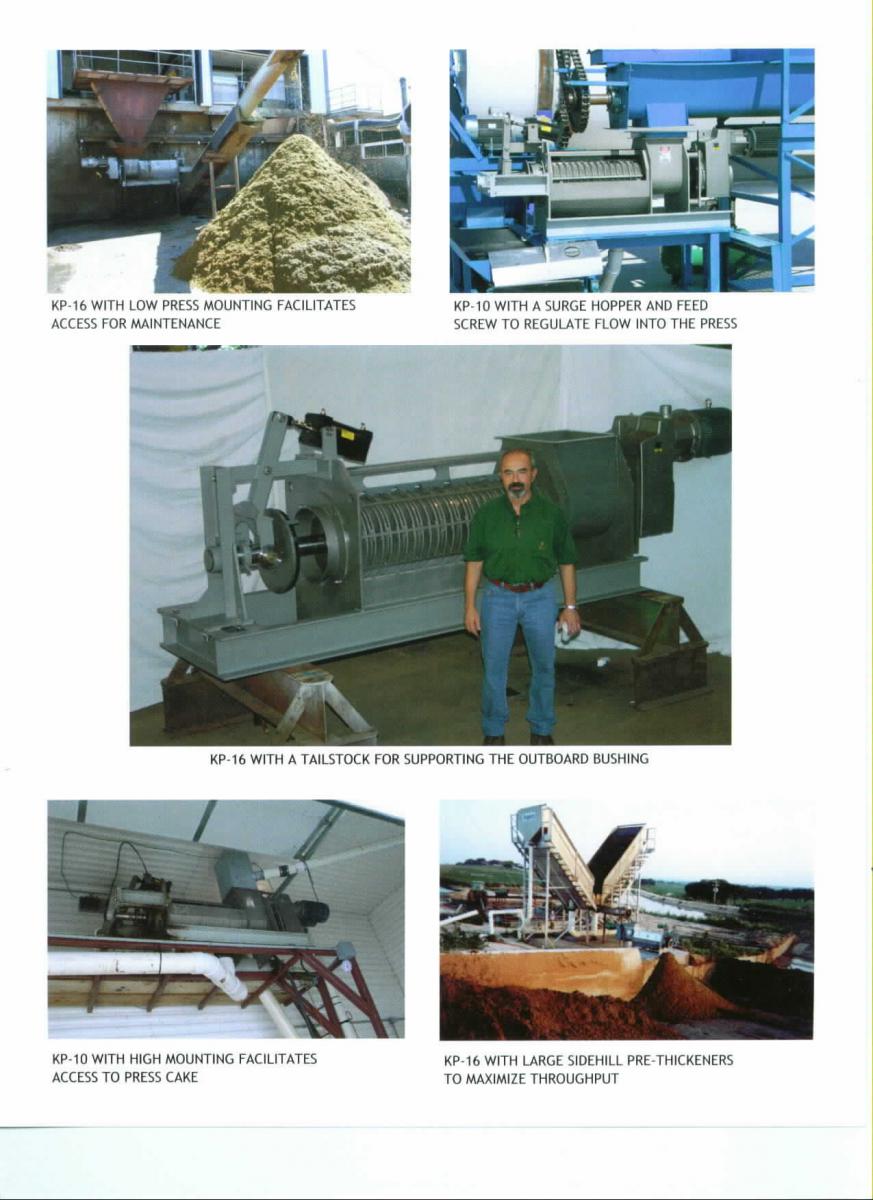

The Series KP Screw Press is a machine in which a screw of progressively reducing pitch rotates inside a cylindrical perforated screen. Material entering the hopper is subjected to gradually increasing pressure as it moves toward the exit end of the press, forcing the liquid phase to extrude through the screen. Dewatering of fibrous materials has proven successful over a wide range of applications. Waste from produce, canneries, plastic recyclers, breweries, poultry processors, and even some paper mill applications, will dewater with excellent results. Pressing is controlled by a discharge cone that provides easy adjustment of moisture content. Stainless steel construction and NEMA motors are standard. The graduated pitch and interrupted flight screw design prevents jamming, while Class II gearbox selection assures long life. The rotating cone feature eliminates purging conditions. Screen sleeve inserts of 3/32″ and 0.033″ perforation are standard; 0.015″ slotted screens are optional.

| Model | Capacity GPM* | Capacity T/HR* |

Screw RPM |

Max HP | Length FT |

Width FT |

Height FT |

Weight Lbs |

| KP-6 | 5-40 | 0-2 | 23 | 5 | 6 | 1.2 | 2 | 800 |

| KP-10 | 10-100 | 1-5 | 19 | 10 | 9 | 2 | 3 | 2,000 |

| KP-16 | 40-600 | 5-20 | 17 | 20 | 13 | 3 | 4 | 5,000 |

| KP-24 | 80-1500 | 20-60 | 26 | 50 | 19 | 4 | 5 | 10,000 |

| KP-30 | 150-2500 | 40-100 | 26 | 100 | 22 | 6 | 9 | 20,000 |

* Subject to feed consistency, bulk density or on-site testing.

|

|

|

|

|

Click the link below for a pdf version of the Series KP Screw Presses brochure.