February 9, 2022

The most common cause of deteriorating screw press performance is wear of the screw. This can cause an increase in press cake moisture content over time. This is addressed by lowering the speed (rpm) of the screw and increasing the air pressure on the discharge cone. Eventually it becomes necessary to inspect the screw.

Or, if the throughput and performance goes bad overnight, one of the flights of the screw may be bent such that flow is being pinched off. This can happen when tramp material passes through the press, or when the press gets jammed. Sometimes the weld between the flight and the shaft is torn. Again, it becomes necessary to inspect the screw.

The easiest way to check for screw wear is to stop the flow into the press, open the cone, and empty the press by running that way for a few minutes. Then knock the remaining press cake out of the end of the press. A long screw driver is usually good enough. But in the case that there is tightly compacted press cake at the discharge, a pressure washer is very effective in removing the material.

Once you can see the flights at the end of the screw, look to see the clearance between the screen and the outside diameter (OD) of the flights. In smaller presses, it frequently works well to reach your cell phone into the opening and take some photos. The original clearance is a tight 3/32″ (2.2 mm). Finding wear such that the gap has reached 3/8″ or more is common. But it may not be the cause of the poor press performance.

To make sure, the next step is to remove the screens of the press so that you can see the complete length of the screw. At that point you may find a bent flight or even a missing resistor tooth. If in question, snap some photos and send them to Vincent.

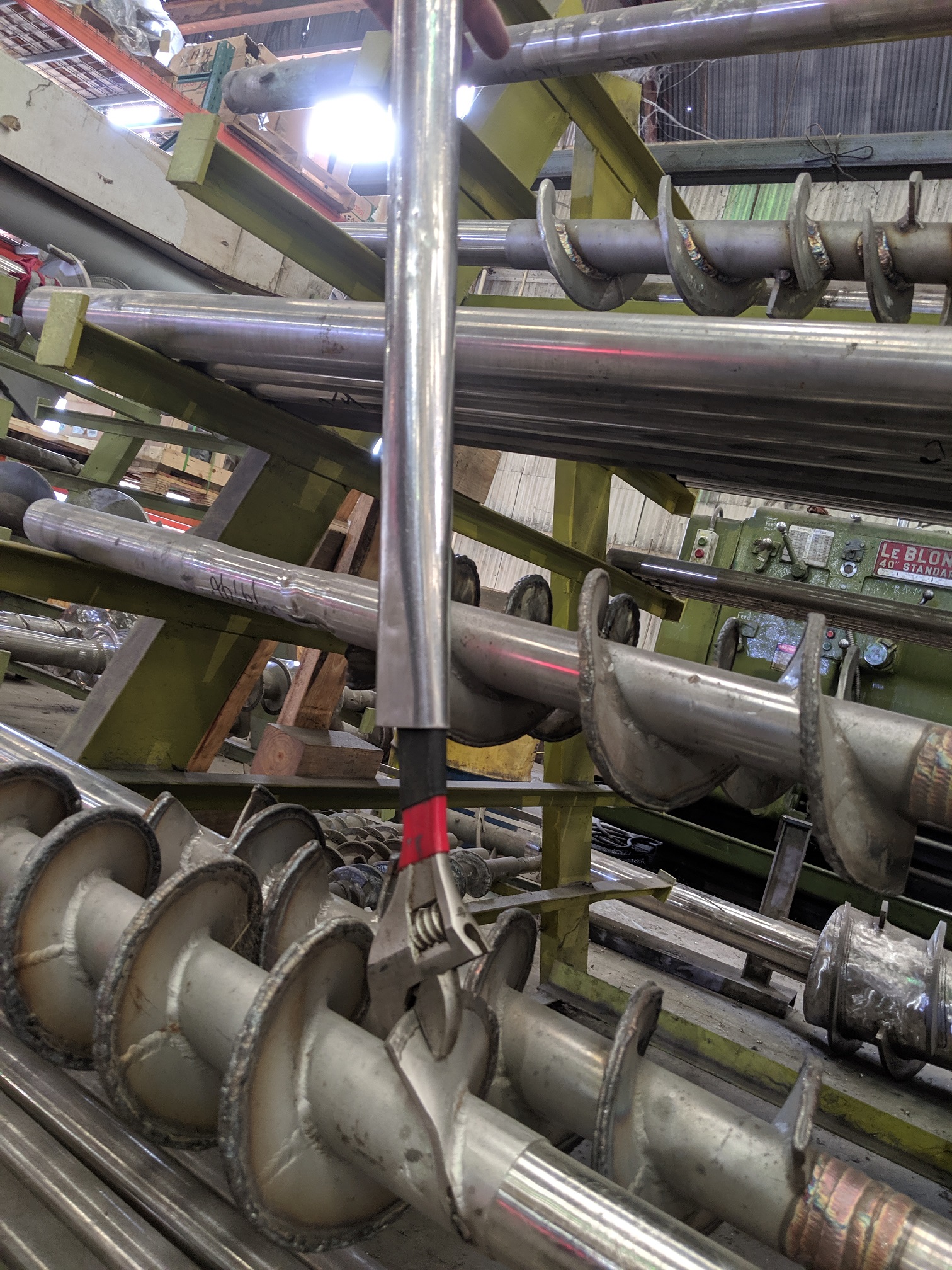

The screw can be checked for wear by holding a straight edge along the flights. The flights in the first half of the screw rarely experience wear, so their OD will still be the original diameter. Look for wear at the discharge end. This is the inspection seen in these two photos:

There is another thing to look for. The outside edges of the flights come from the factory with weld applied hardsurfacing which has been ground to a sharp edge. If wear has occurred, they may have become rounded over, as seen in these photos:

Rounded edges tend to act like a putty knife, pushing material into the screen and plugging the openings. The restoration can be an easy job. Vincent can correct this in the factory.

The photos below will help you spot problems with a screw.

Incidentally, there is an excellent Pressing News #326 which details how to remove a screw from a hollow bore gearbox.

ISSUE #340