MAY 22, 2015

The Permawick Company, a manufacturer of specialty lubrication systems, is headquartered in Birmingham, Michigan with manufacturing facilities in Michigan, Indiana, and Japan. They utilize a Vincent screw press to recover oil from their reject PermaWick engineered fiber-oil lubrication products.

Years ago Permawick was best known for the little felt lubricating washers used in automobile generators and starters. Today their engineered fibers provide permanent lubrication for sleeve bearing systems, and they are the industry standard for Fractional Horsepower Electric Motor lubrication. The Permawick technology has replaced oil-soaked wool felts, which were messy, consumed critical space and absorbed water.

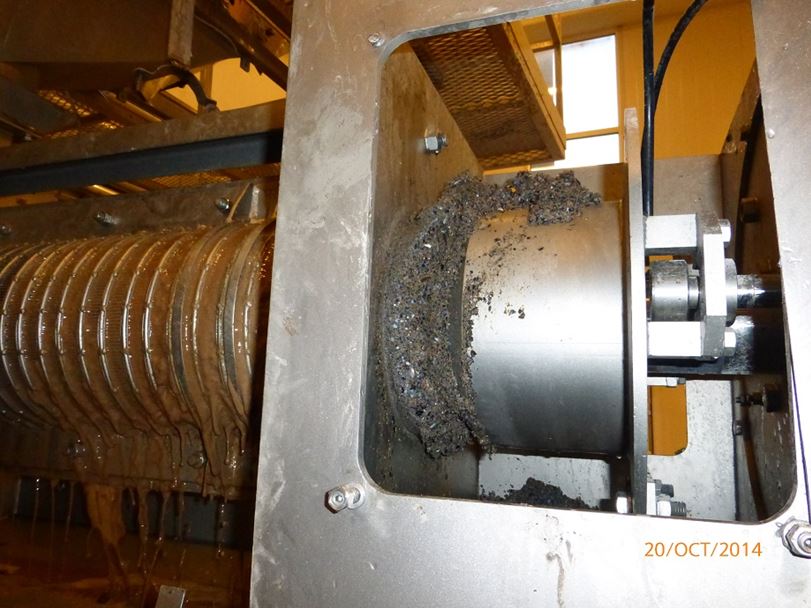

Two years ago, an opportunity developed to salvage oil from fiber-oil lubricators which failed to pass inspection. A significant quantity had accumulated and Permawick rented a Vincent model CP-4 laboratory screw press to process this waste. Since the lubricators are 85% oil by weight, 99% oil by volume, the potential for oil recovery was of high value to the company.

A year later, the problem was re-addressed by the rental of a significantly larger Vincent screw press, the CP-10. While this press achieved far greater processing rates, the residual oil in the fiber press cake was excessive, yielding only a 30% oil recovery rate.

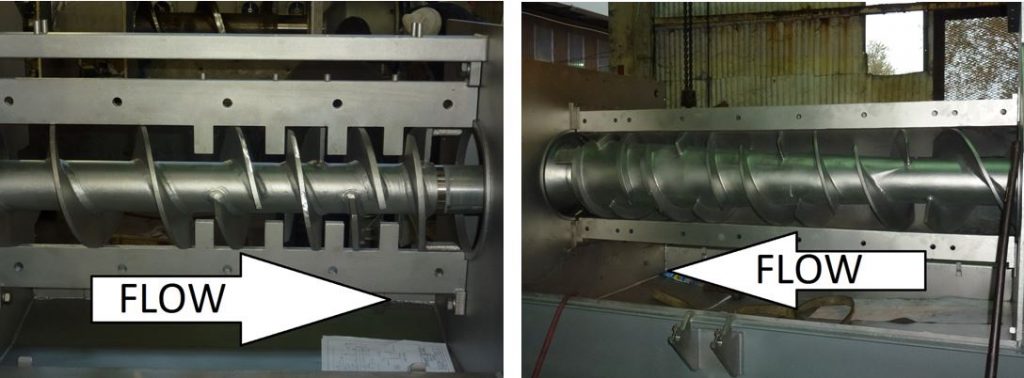

In an effort to improve this, Vincent supplied a tapered shaft replacement screw for the press. The tapered shaft configuration pushes the material both outward and parallel to the shaft, thereby increasing compression of the material. The results were superb; oil recovery increased to 70%.

Issue 273