June 20, 2023

As a rule, Vincent screw presses have plenty of hydraulic capacity. That is, the open area in the main screens which surround the screw is a lot more than is needed for all of the liquid to be squeezed out. However there are cases where, when a dilute flow is being fed into a screw press, additional area is needed.

Often this problem is taken care of by mounting a sidehill (static, parabolic) screen over the inlet to the press. Vincent builds these when they are needed.

Another solution is to mount a screen in the bottom of the inlet hopper of the press.

The trick with inlet hopper screens is to recognize that the screw is not pushing liquid through that screen. In contrast, once the flow enters the main screened area, the configuration of the screw is such that the screw applies pressure on the material, forcing liquid through the screen.

The result frequently is that the solids in the flow entering into the press tend to settle in the bottom in the inlet, blocking the flow of liquid through the screen. Because of this, inlet hopper screens often need to fit closely against the screw.

In order achieve this, the inlet hopper screen needs to have some flexibility so that it can be positioned to wrap against the screw. The screen needs to be able to wrap at both the bottom and the sides of the screw.

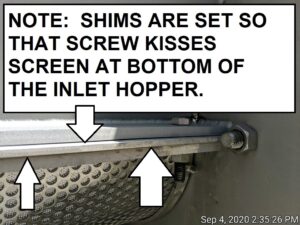

To allow the inlet hopper screen to fit tightly against the bottom of the screw, removable shims are used which allow the screen to be raised upward against the screw.

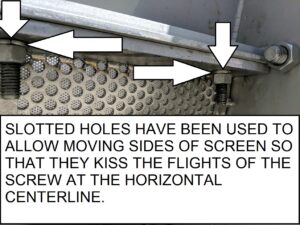

At the same time, slots, rather than holes, are used in bolting the flanges of the screen onto the inlet hopper. This allows the sides of the screen to be positioned with a slight contact with the screw. This means that the supporting frame of the inlet hopper screen must be somewhat flexible.

The main screens of a press always have a honeycomb structure which makes a rigid structure with great burst strength. That is needed because of the compressive forces created by the screw.

In contrast, the only pressure against an inlet hopper screen is the relatively light static hydraulic head pressure which results from the depth of fluid in the inlet hopper of the press. For this reason, an inlet hopper screen does not need the burst strength of a main screen.

The photos below show these design characteristics.

ISSUE #350