ANIMAL FEED AND BIOFUEL

At least once a year we are approached by entrepreneurs who conceive a system for converting garbage into animal feed. The garbage in question is frequently restaurant waste, although it may also be institutional or even residential waste.

Invariably these projects collapse under harsh realities.

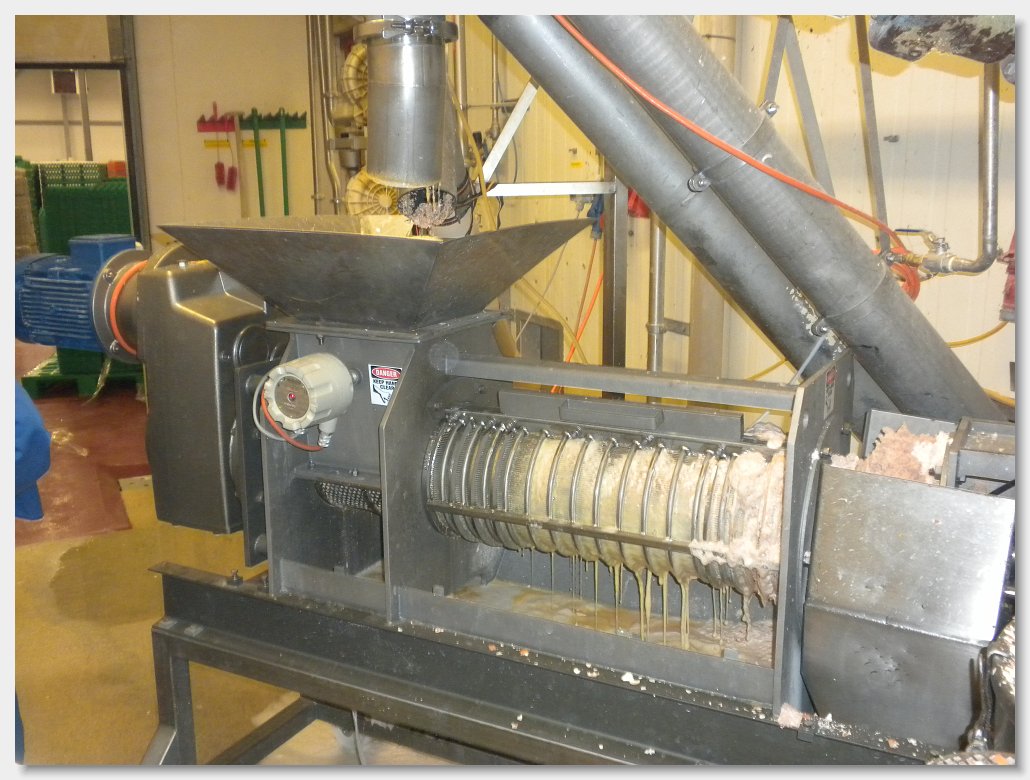

The request is frequently made for a screw press that will dewater the waste to some unrealistically low percent moisture, like 50% or less. In reality, garbage is 85% to 95% moisture, and, after pressing, the press cake will still have over 80% moisture content. At that point there is no more free liquid to squeeze out of it.

Specifying a machine to remove more moisture means nothing if a machine cannot do it. Pressure in a screw press will remove only so much moisture. After that, the solids will extrude through the screen like thick milkshake. To remove additional water, a change,caused by chemical reaction or adding heat, will be required.

In order to prevent spoilage, the moisture content of an organic material must be reduced to a range of 10% to 15%. This dehydration must be done in a rotary drum dryer, and the fuel costs will exceed the value of the dry garbage. That is, to produce a ton of 12% moisture material from press cake with 80% moisture, the dryer will require over one hundred therms of energy. That is more than $50 worth of fuel alone to produce one ton of animal feed.

Besides this, pressing garbage to remove the moisture creates an impossible sewage disposal problem. The press liquor from pressing garbage is a thick goo of suspended solids. The BOD loading of this liquid will overwhelm most wastewater treatment systems.

In addition, the labor costs to remove contaminants are significant. Restaurant waste typically has plastics (shrink wrap and Styrofoam), metal (silverware and coins), string and cord, not to mention broken chinaware, glass and pop cans. Farmers are reluctant to buy feed that might contain these items, even at discounted prices.

None of this seems to faze our would-be garbage millionaires. What should bring them down to earth are two facts: (1) the opportunity they see has been obvious in America for at least a century, and no one has made a go of it, and (2) nobody has made a go of this business potential in third world countries where labor is cheaper, farmers are less picky, feed is more expensive, and businesses are less encumbered by environmental regulations.

November, 2010. More recently garbage inquiries have focused on biofuel applications. A key bit of logic is as follows: before something can be burned, all the water must first be removed. In this water evaporation process, a point is reached at which there is only 10% moisture left. If we freeze the system at that point, an analysis of value will show that the material at 10% moisture has greater market value as animal feed than it does as boiler fuel. The only exception we have found to this is in Europe where use of biofuel is being mandated by government regulations. Pity their taxpayers.

ISSUE #141