Almost all Vincent presses use screws with the interrupted flight design. Built with anything from three to seven stages of compression, there is a gap in the screw flighting for each stage of compression. Resistor teeth, fixed from the outside of the screen, project through the screen into these gaps. The purpose of the resistor teeth is to prevent co-rotation of the material in the press. In addition they cause agitation within the press, which stirs wet material against the screen of the press.

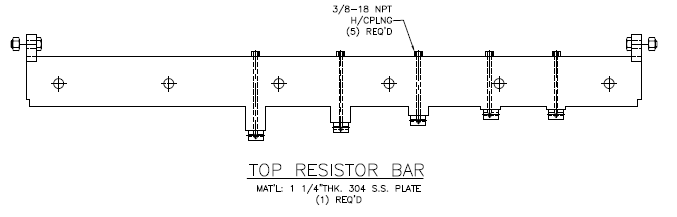

These resistor teeth can be drilled for yet another function. By drilling holes the length of the teeth, it is possible to pump fluid from the outside of the press into the material being pressed.

The most common application is to pump CIP water through such passages. This allows the press to be flushed internally with water or caustic solution during shut-down periods. Such a feature may eliminate the need to disassemble the press for cleaning purposes.

Another application is to inject steam into the material which is being pressed while the press is in operation. The blanching action that results can result in significant additional moisture removal by the screw press. Pressing News #129 of July, 2002 tells how an additional four percentage points of moisture removal were achieved in citrus waste by injecting steam.

Probably the most common application is where it is desired to wash the material that is being pressed while it is being pressed. Sometimes solvent is pumped through the resistor teeth. This is done with the press in operation. It is handy where solvent is used to extract solubles in a material. In a similar application, water is injected to help wash solvent from a material being pressed.

Hot water can be pumped into a press that is pressing coconut meat, resulting in a higher yield of flavors and dissolved solids from the coconut meat. This is done in the production of Coco Lopez, cream of coconut.

Crown Iron Works did some work with a lab press where the possibility of injecting super critical carbon dioxide was considered. This, too, is a solvent extraction application.

The cost of drilling resistor teeth and fitting them with a pipe coupling is so slight that it is provided at no charge when the customer has a need for it.

The photos show small presses fitted for fluid injection.