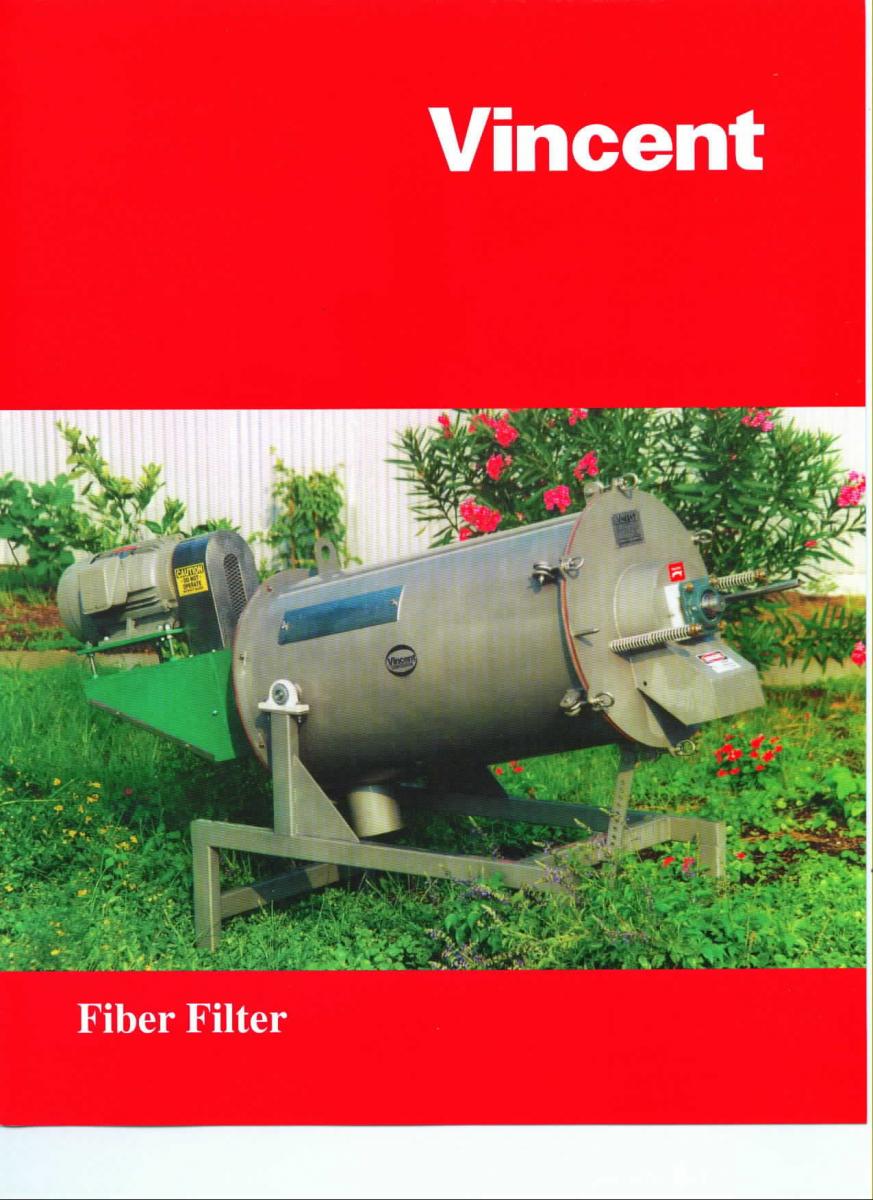

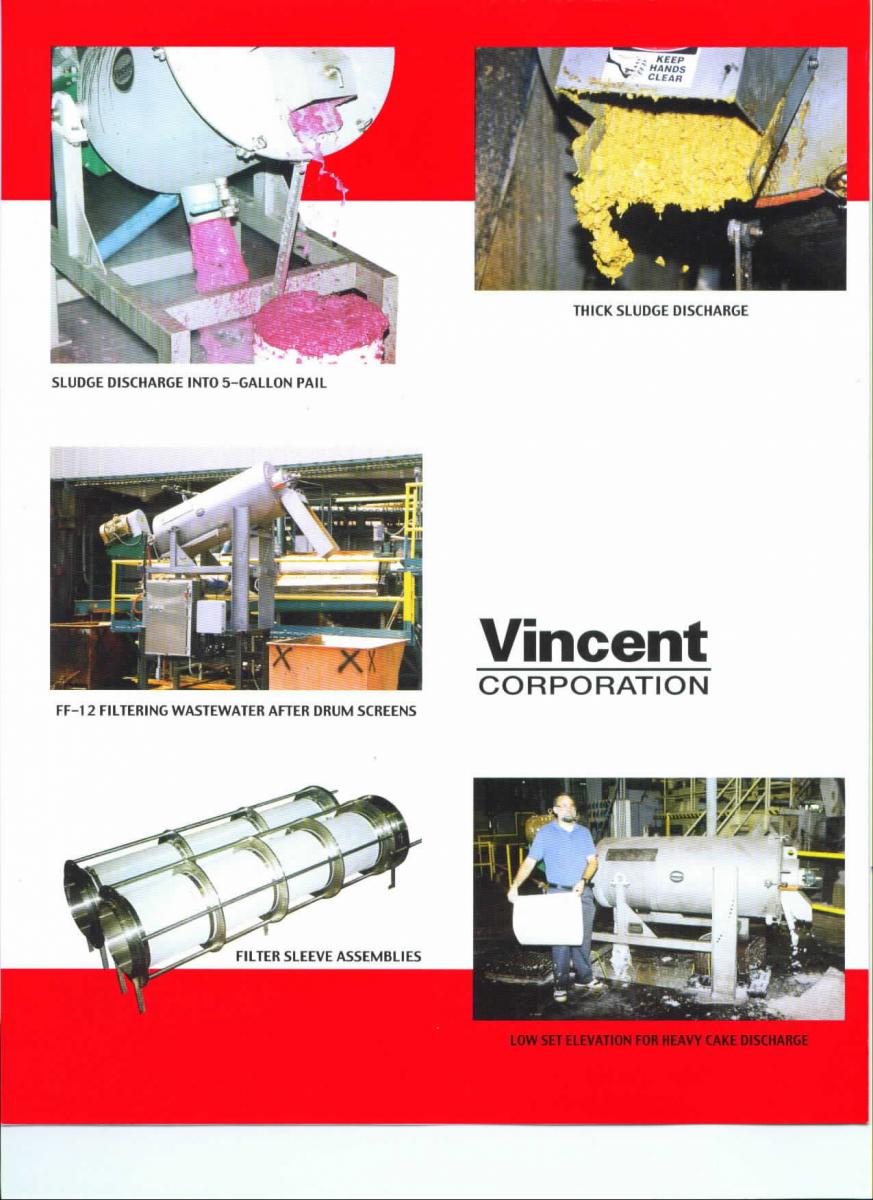

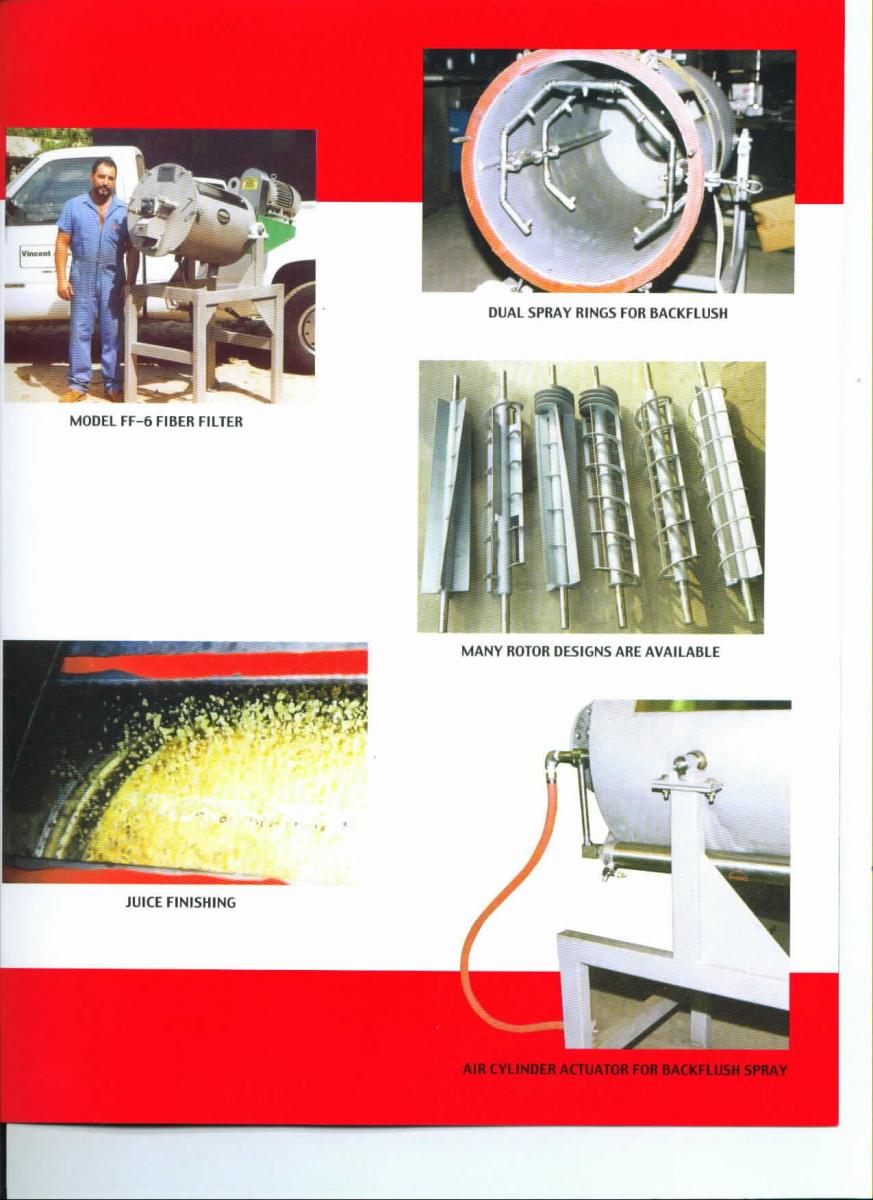

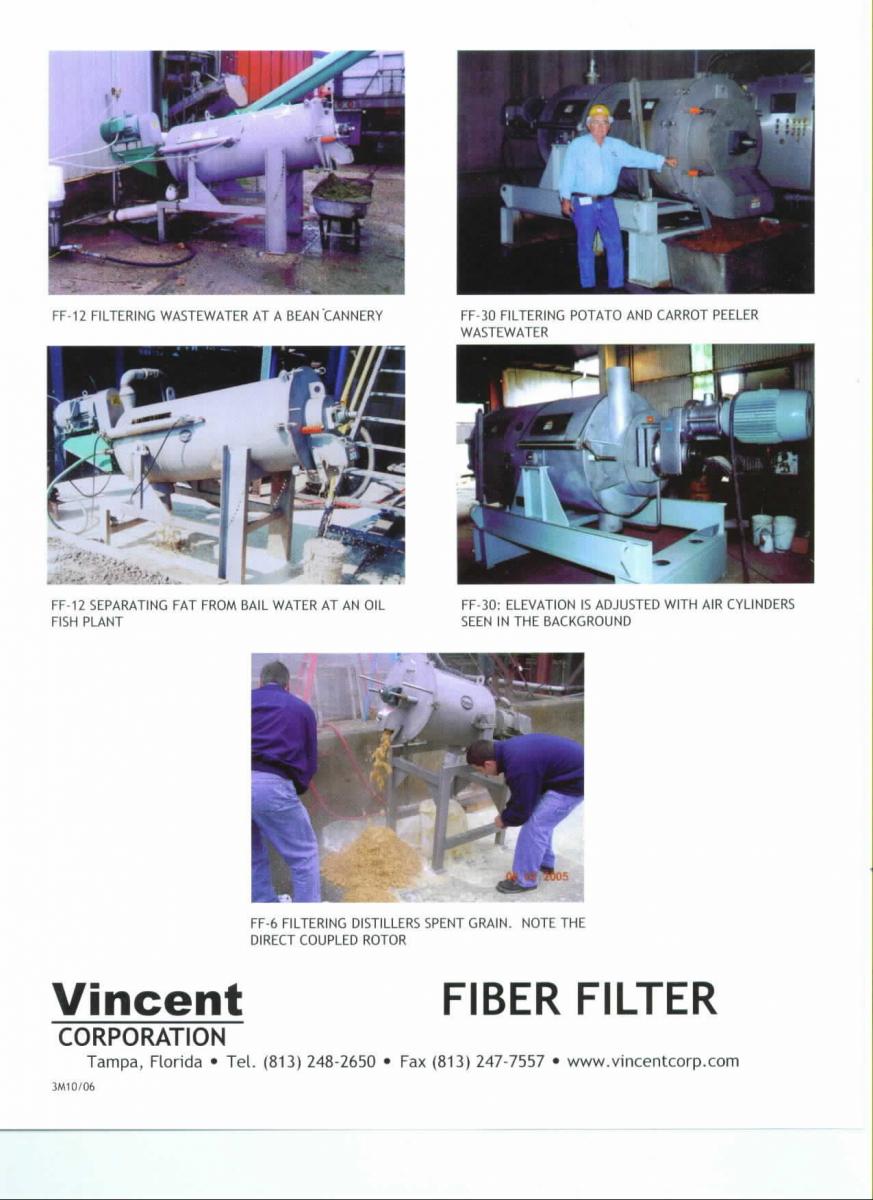

Fiber Filter AdvantagesFeaturing fine filtration of high gpm throughputs, the Fiber Filter is a unique machine. It operates continuously with a fabric filter that is vibrated clean by the process flow, requiring only occasional back-flush cycles. Liquid flows with fiber contents ranging from 0.3% to 1.5% are thickened to a range of 4% to 14% solids with the Fiber Filter. The filtrate liquid is remarkably clear. The Fiber Filter can replace equipment ranging from pre-thickening screens to centrifuges. Fiber Filters can be used both to thicken flow ahead of a screw press and to remove fiber from press liquor. Common Applications of Fiber Filters

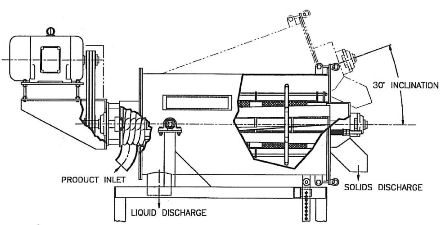

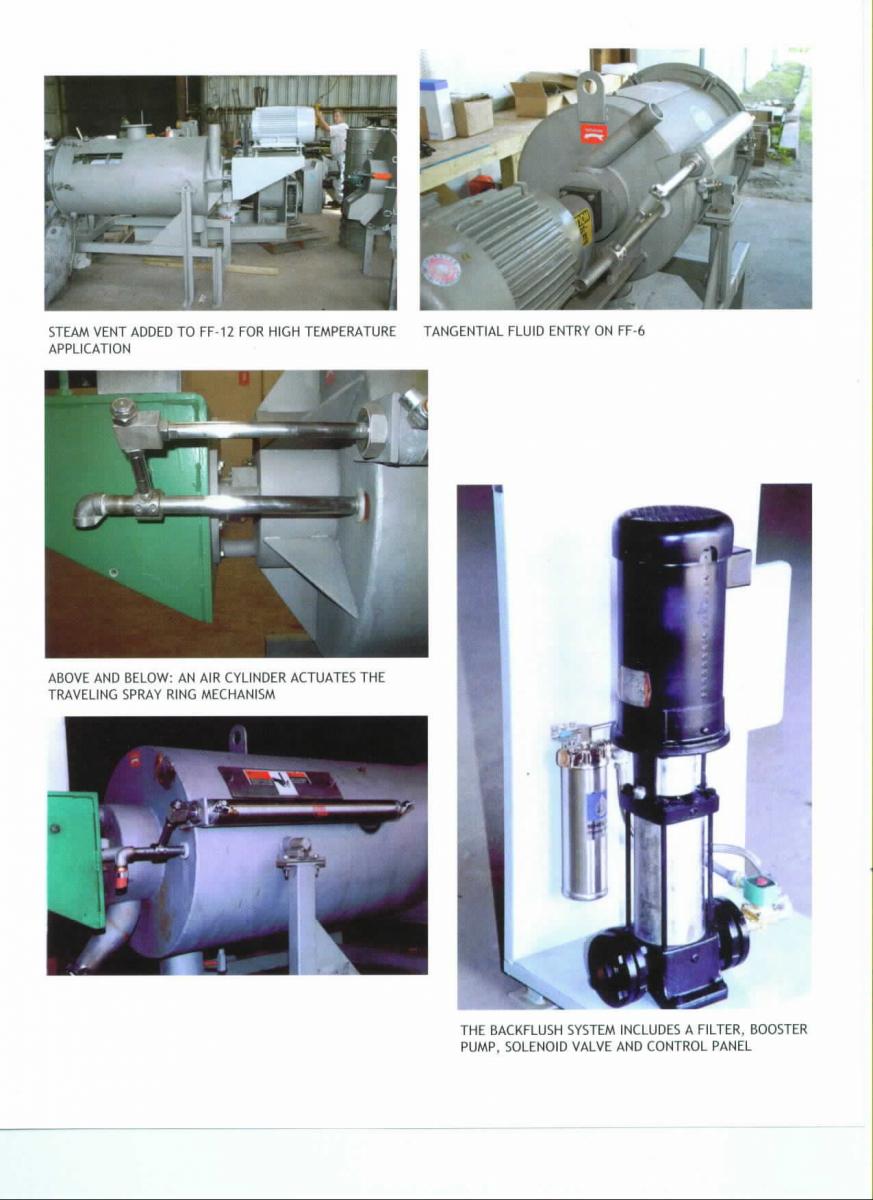

For more detail regarding applications see Fiber Filter II. Mechanically the Fiber Filter has a rotating paddle impeller that whirls and pulses the incoming fluid against the inside of a cylindrical filter screen. The filter sleeve, held taught in a frame, is made of a woven polymer fabric. The fabric is available in meshes ranging from 25 microns (0.001″) to 300 microns (0.012″). Fabric tension is adjusted from outside the machine, improving sanitation and facilitating operation.* Back-flusing may be required to maintain peak throughput capacity. A wash nozzle manifold for use with water or filtrate is included with all machines, along with a booster pump and control panel. * US Patent 6,117,321

|

|  |

|  |

|

Click the link below for a pdf version of the Fiber Filter brochure.