Back in the days when Vincent manufactured drum dryers, we frequently included a Cooling Reel with the dryer. Dan Vincent even patented some of the features. Dried material leaving the cyclone separator at the discharge of the dryer was conveyed to the Cooling Reel. The stated purpose of the Cooling Reel was to reduce temperature of material leaving the dryer before the material went to storage.

An added advantage of the Cooling Reel was that the moisture content of the material was reduced by another one or two percentage points. This small removal of moisture was economical because it was achieved by drawing ambient air through the Cooling Reel.

Vincent Cooling Reels were supplied with a cyclone which was used to capture fine particles which would be drawn through with the air flow.

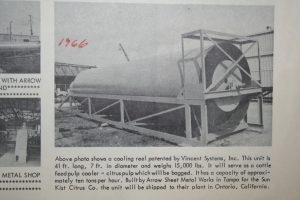

Mechanically, the dried material entered the Cooling Reel at the upper end of an inclined reel. The material tumbled over internal flights to the discharge end, while a counter current flow of air was drawn through the product. Our most recent (1981) brochure lists seven models, in sizes of 2′ diameter by 10′ long on up to 7′ diameter and 35′ long.

It was only in the last month that we observed that a major function of a Cooling Reel is to separate burned fines from washed and dried pectin peel. It is common for fine particles to burn in a drum dryer. In the case of lemon and lime peel which is being sold to pectin producers, these black specs are quite undesirable. The photos which follow show how a Cooling Reel separates these particles.

1980’s VINCENT COOLING REEL AT CI PRO SICILIA

COOLING REEL AND CYCLONE IN ROTARY FEEDER AT

TUCUMON, ARGENTINA BOTTOM OF CYCLONE

BAG OF BURNT SPECS BURNT SPECS FROM COOLING REEL