When he read about pressing eggshells on the Vincent web site, an engineer at a fishmeal plant in Norway thought that he had found the perfect machine for his project. He emailed Vincent explaining that he wanted to run blue mussels through a screw press. We Googled “blue mussels” and wrote back that we enjoyed blue mussels at restaurants, but we were sure we would make a real mess of them in a screw press.

One email led to another, and soon RUNI, our agent in Europe, provided a small KP-6 press for lab testing. Sure enough, puree of mussel came through the screen, and the press cake looked like piles of coarse wet sand. This success led to our participating in trials in October in the pilot facility of Farmsund Fiskemel in the fishing port of Alvaldness. A Model CP-10 press from the rental fleet was used.

The idea is to run the mussels through the press in order to separate stick water from shell. The stick water (press liquor) is made into dried feed for salmon farms. The shells will be similarly dried and made into chicken feed. This layer feed, rich in calcium and protein, improves the color of egg yolks.

This blue mussel project is probably going to need some government support. They call it integrated harvesting: the severe fecal load from the salmon farms is balanced by the fact that mussels consume algae which has grown off the biological load that has been added to the sea. On a global basis it pencils out. They call it environmentally sound salmon farming.

The mussels are grown 15 kilometers upstream in the fjords, on rope nets about 5′ wide and very long. These nets are hung vertically from floating pipes. The mussels take six months to one year to grow to the right size. They are harvested with boats which use something like car wash brushes. These sweep the mussels from the nets, and they are pumped up aboard the boat.

We started with a ton of mussels and had superb results. The shells cracked uniformly into small grains, and a flood of press liquor came out. That was fine except that the 16 amp motor was running 30 amps and higher, at 5 psi cone pressure. So they switched to a 24 amp motor. (That is, we switched from a 10 hp to a 15 hp motor.) Fortunately we had selected a gear ratio suitable for 50 Hz, with an IEC motor adaptor. That left us with a 1.0 service factor on the gearbox.

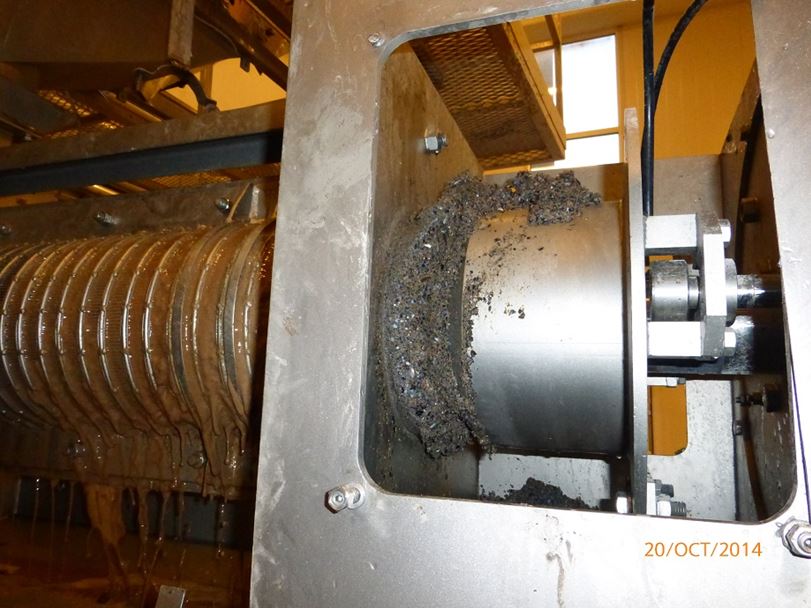

The amps still were still around 30, and we tripped out. So we decided to reduce the tapered portion of the screw shaft. Originally it went from 4″ to 7-1/2″, and we got it down to about 6″. The motor load went down to 18 amps, at 75 psi cone pressure, so we were able to run a few hundred tons of mussels, producing samples of product material. This screw modification took only three hours; it was done without removing the screw from the press.

The production process involves heating the stick water (press liquor) to 85C, which coagulates it. A progressive cavity pump circulates the stick water through the tubes of a horizontal steam heater. Next it is run through a Flottweg decanter and then to a single effect vertical tube evaporator. It is concentrated to 40% DM. This is mixed with the sludge from the decanter and dried into granular form. The steam dryer uses product recirculation, like the old Vincent dryers.

For the production of chicken feed, the shells (press cake) are run through the same dryer. This material must have protein as well as calcium, so they do not want the press to remove all of the protein matter. (That is just like our jucca press.) It looks initially like we were leaving too much protein in the shells, but that problem can be solved with a larger gearbox and the right taper on the screw shaft.

The mussels are extremely abrasive. After running only one ton of mussels, the flights of the screw were showing polish. This will be addressed with Tungsten Carbide hardsurfacing. Fortunately, based on our eggshell experience, we had increased the screw-to-screen clearance to 1/16″. Even after running 30 tons there was very little, if any, screen wear evident. Swirls where we had buffed the screen were still clearly visible. (While reducing the screw shaft taper, we cut off the wing feeders. This improved operation and reduces the chance for screen wear.)

The 0.015 slots in the wedgewire screen proved good for this application. The amount of shell fines in the press liquor was manageable.

As we do with eggshell, the discharge cone design will be modified to one that uses a 4-bar actuator mechanism. This eliminates the cone bushing, which would surely be a wear point.

We were delayed in getting a second load of mussels because most of the boats were tied up cleaning the nets of the salmon farms; these nets must be brushed free of algae every five days. This fresh load of mussels came from an abandoned farm where they had been allowed to grow for three years. They were much larger, with heavier shells. There were even some oysters and scallops in the load. The flow of press liquor was noticeably less than with the smaller mussels. Still, good results were obtained.

The pilot plant’s control technology is very advanced. There is a control room where video feeds show in one corner of the screens. But, the plant is run from a tablet the operator carries around the machinery. He can start, stop, and control speeds of the conveyors, press, and pump, all from the tablet. Also, the managers can do this from their cell phones!

We started with an ultrasonic level control on the screw press, but the beam was not narrow enough. So we switched to a radar beam, but there was too much ambient noise. So by noon of the first day a hinged panel, which hangs in the middle of the inlet hopper, was installed. As the hopper fills, the panel swings to hit a limit switch which stops the belt conveyor which feeds the press. It works perfectly, keeping the press fully loaded at all times.

Now, the next time you enjoy steamed mussels at a restaurant you will have something to talk about.

Issue 268