Vincent Corporation has extensive experience with dewatering spent coffee. With spent coffee the press cake comes out at around 58% moisture content, depending on the extraction process used.

Most soluble coffee producers burn their spent coffee because of its high BTU content. Historically, either grate furnaces or fluidized bed boilers have been used.

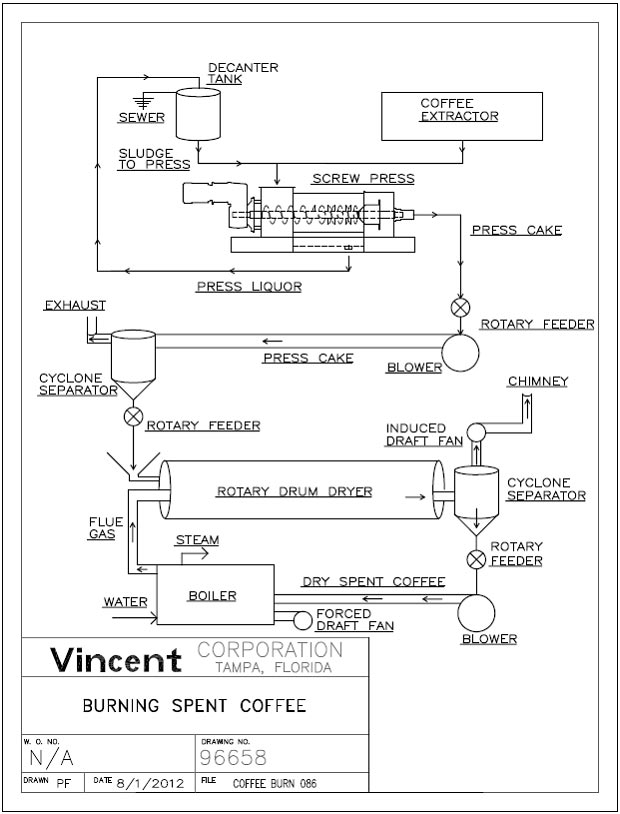

A much less costly, but equally efficient, method of burning spent coffee is common practice in Colombia. They take the press cake from our screw presses and dry it down to 10% moisture content in a rotary drum dryer. This material can be burned in a conventional boiler, without the cost and complexity of a fluidized bed unit. In fact, the boiler is relatively inexpensive because it is deliberately undersized. Being undersized, the chimney gasses come out quite hot. Rather than put these flue gasses out the stack, they duct them to the drum dryer. In this manner the flue gasses are used to dry the press cake down to a required 10% moisture content. At this low moisture, the cake burns in suspension, like pulverized coal or natural gas. There is no auxiliary fuel required in the boiler (except for start-up). There is no burner or furnace on the dryer, either.

The boiler is an unusual design. The furnace is a conventional water tube construction. However, at the top exit of the boiler there is a fire tube section for pre-heating the feedwater coming into the boiler. This seems an odd combination, but it must work since the Colmaquinas, Hurst and Cerrey boiler companies all offer it.

The chart showing this system is attached.

This same combustion system would work equally well in burning a variety of biomass by-products.

Issue 241