|

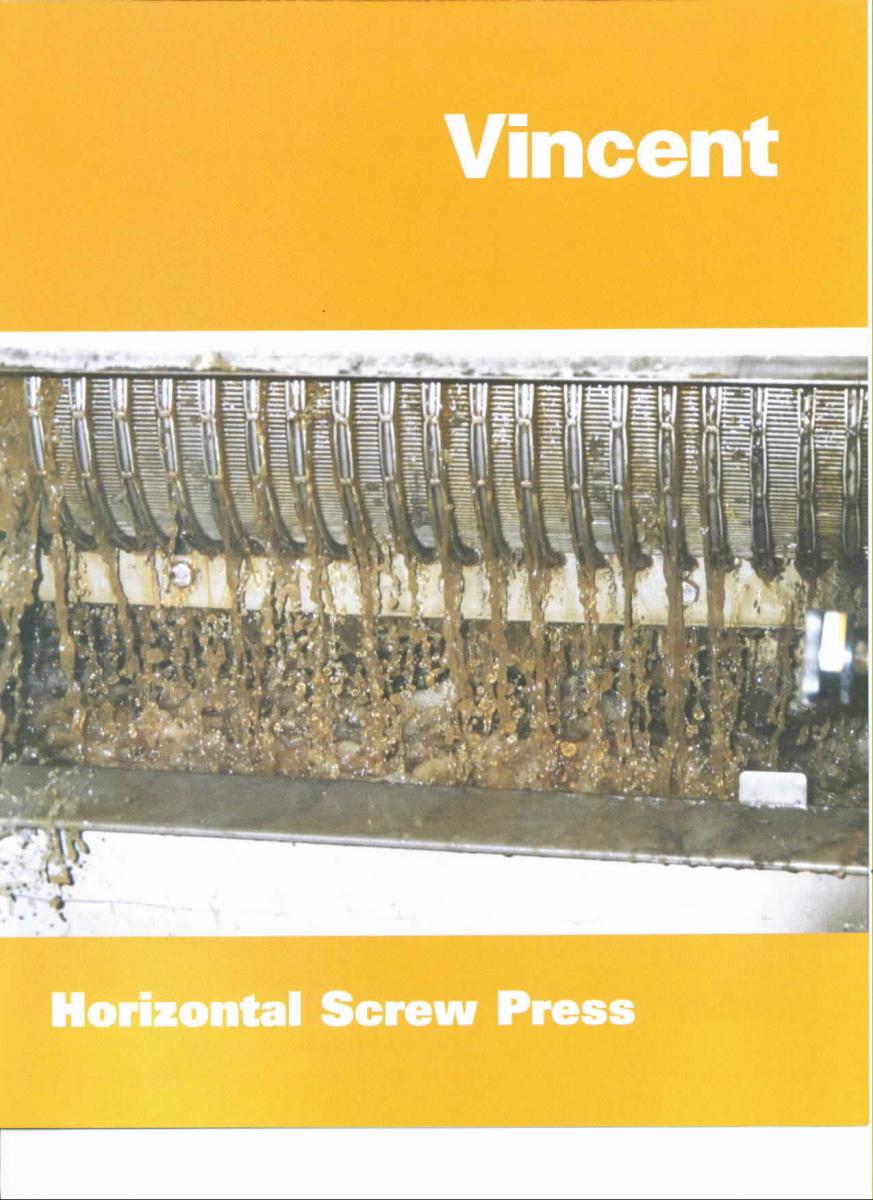

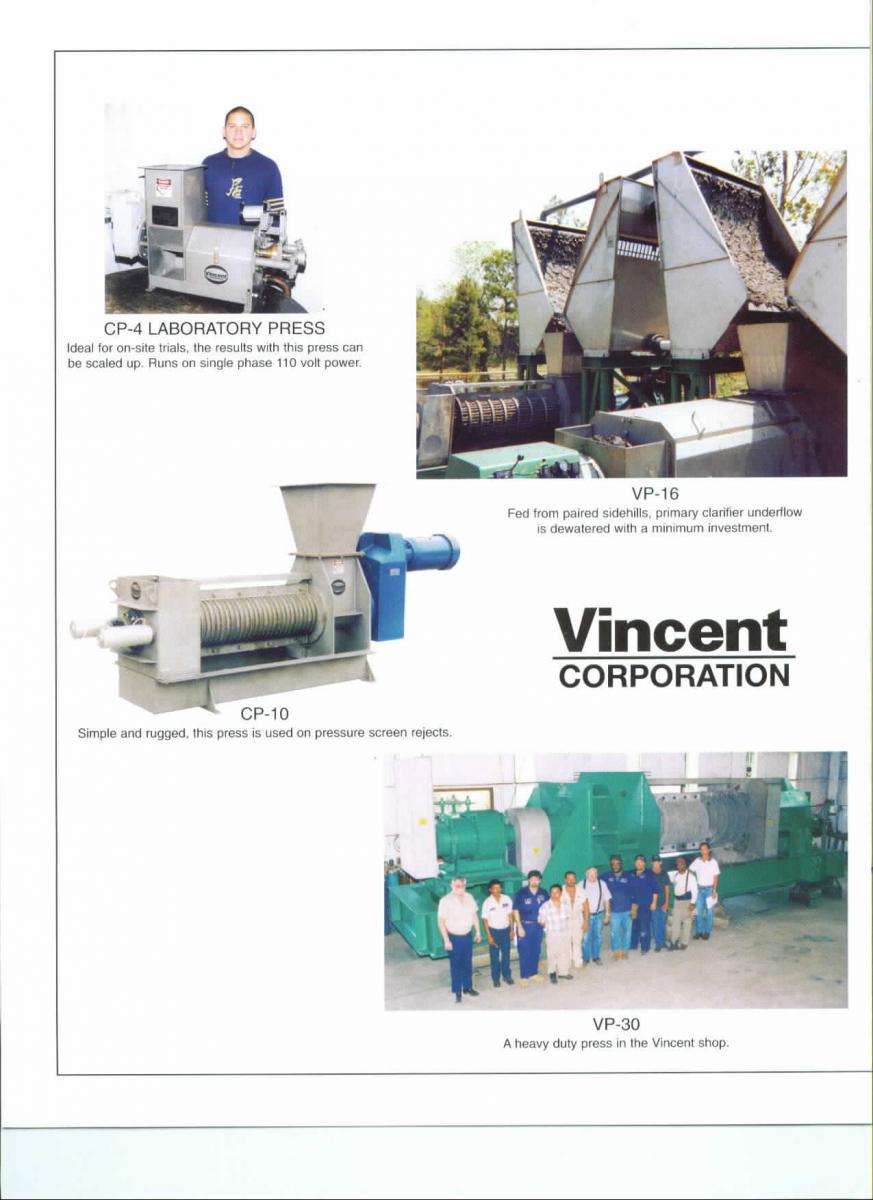

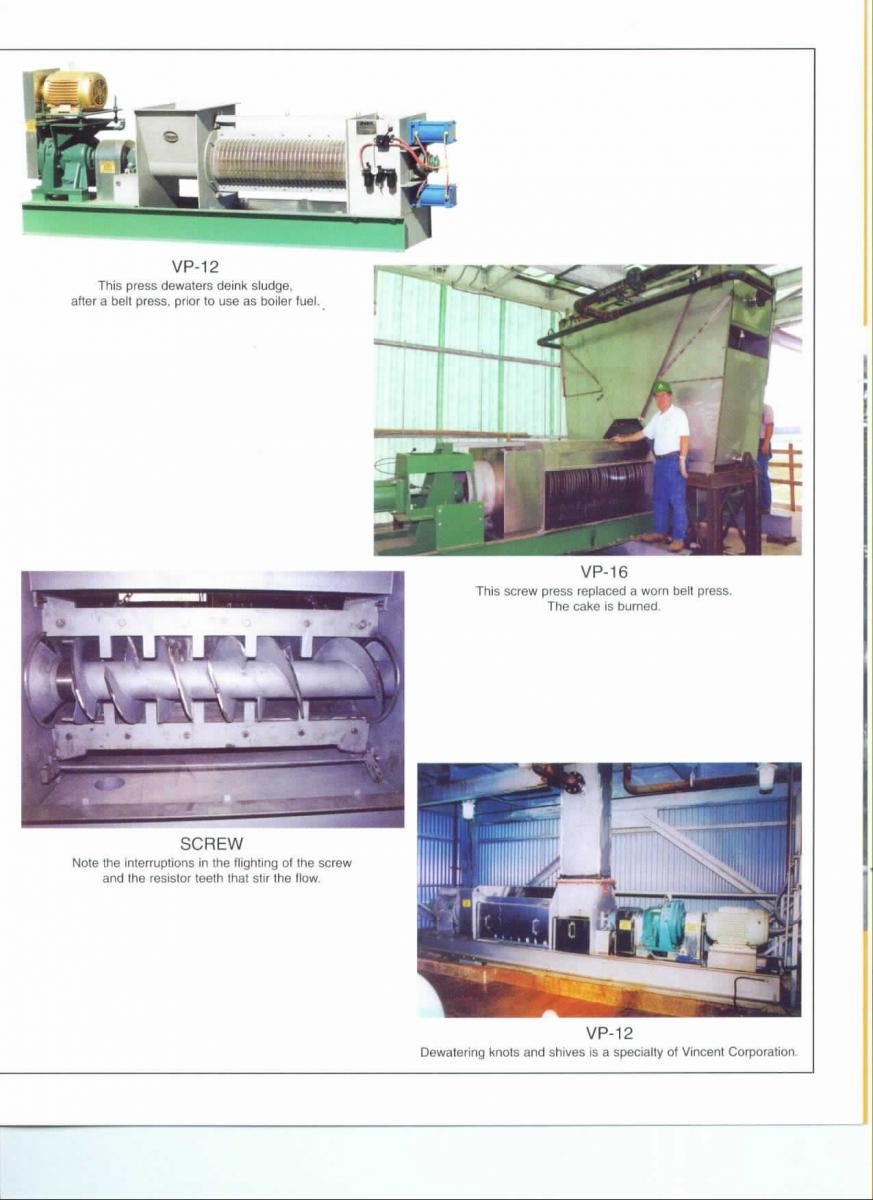

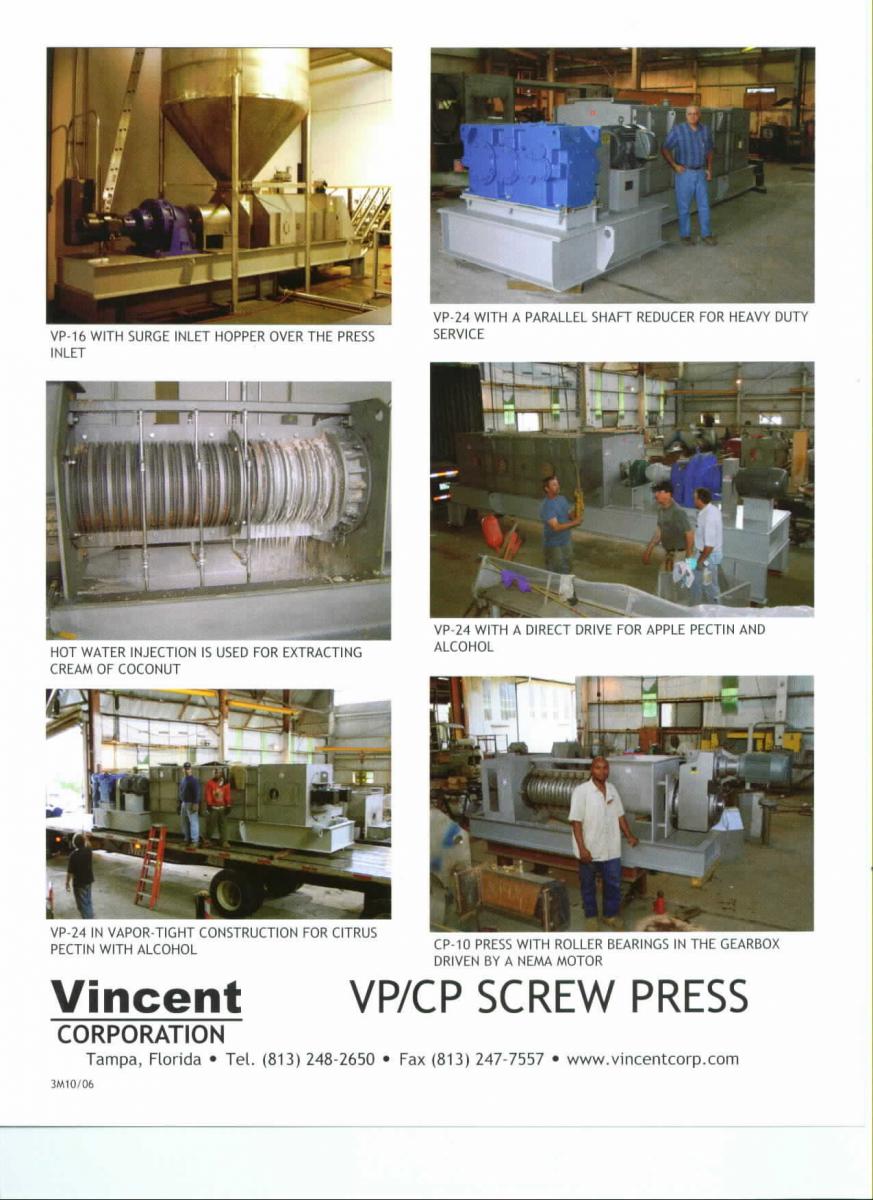

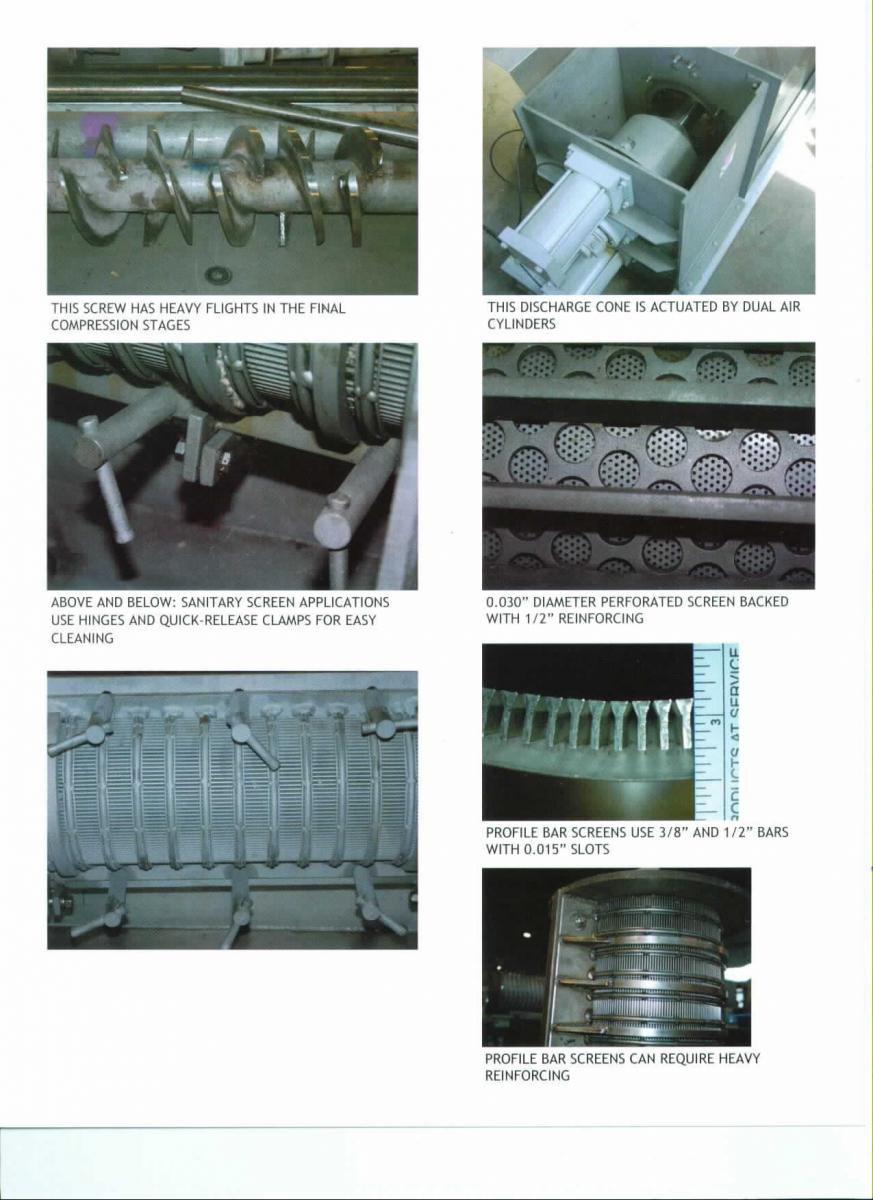

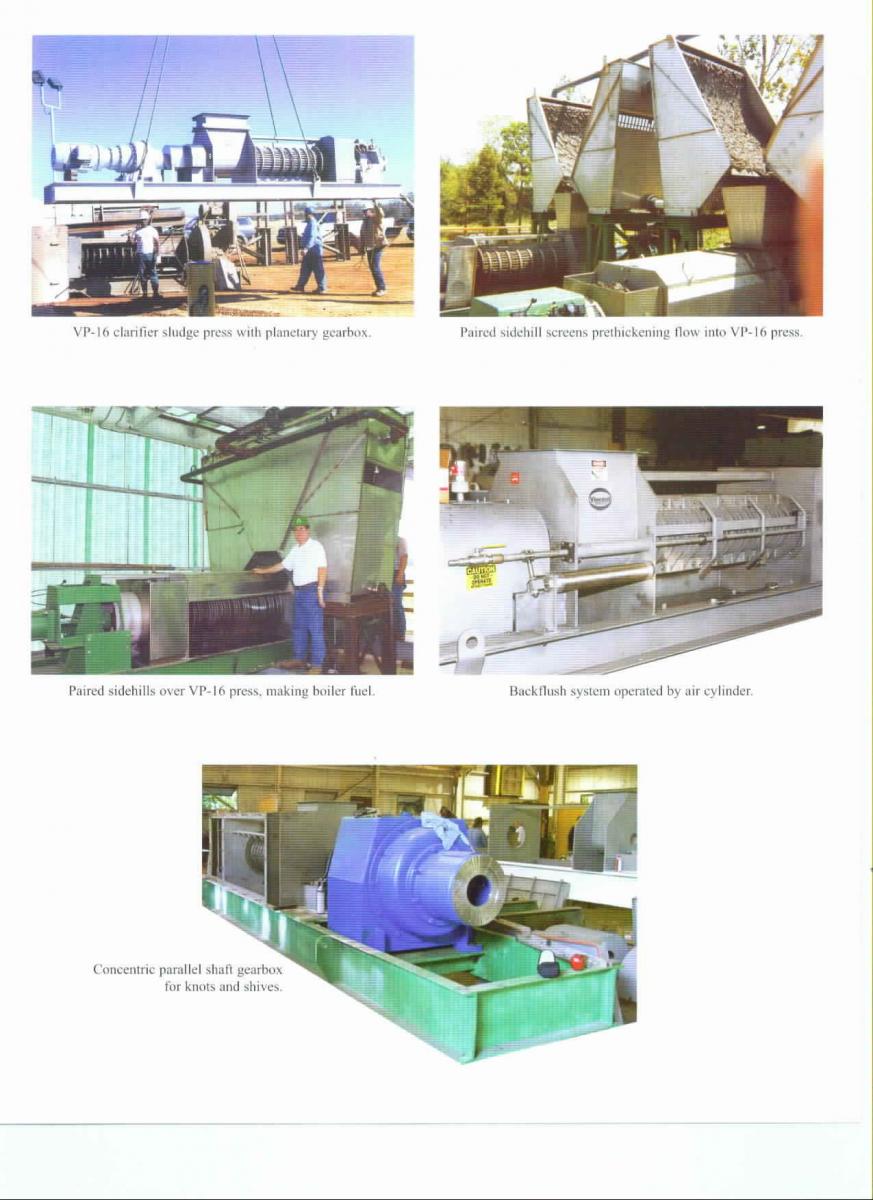

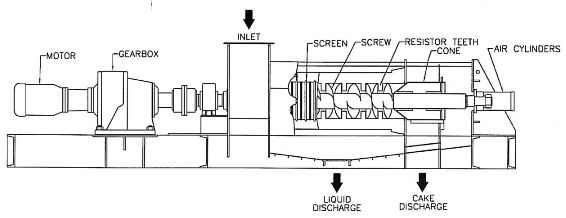

The Vincent Screw Press is a continuous dewatering press that has proven successful in both virgin fiber and recycle mills. It has a graduated pitch, interrupted flight screw. Final pressing is controlled by a discharge cone, actuated by an air cylinder, providing easy adjustment of moisture content. Profile bar (wedgewire) screens and hardsurfaced wear areas are standard. Excellent service is obtained on screen rejects, shives, knots, and primary clarifier underflow. Inbound consistencies of 2% to 20% solids are accepted (without adjustment to the press). Press cake moisture is controllable in the range of 25% to 55% solids. The Series VP presses use a foot mounted gearbox, while the Series CP’s use a hollow-shaft gearbox. All gearboxes are rated for Class II service. Dilute materials can be pumped directly into the screw press. Sometimes pre-thickening is required, typically with a sidehill screen. Because the screw design, with interrupted flights, improves performance, these presses typically operate at constant speed. No variable speed drive (VFD) is required. Laboratory and pilot plant models are popular. Vincent maintains a very large fleet of rental presses. These are available for on-site testing and demonstration. Samples are run at our Tampa Works at no charge.

* Subject to on-site testing

|

Click the link below for a pdf version of the Horizontal Press brochure.