The first Vincent heard of pods and pillows was in early 2011. Within months of each other we received phone calls from companies who had found us on the internet. Both were quite secretive and had little to reveal even after we had signed Non Disclosure Agreements.

Both had capsules with some sort of liquid inside. They wanted to run these through a screw press in order to separate the liquid. It sounded much like the work we had just completed in developing a press to break open gel caps to separate oil emulsion pharmaceutical from the cap material. Only in this new case the articles we were to press were the size of golf balls.

One company called them pillows and the other, pods. One company was a firm contracted to dispose of waste and reject material for Procter & Gamble. With the other company we were dealing with a research office in Scottsdale, Arizona.

Today most housewives in North America are familiar with what we were working with. A revolution in laundry detergent has taken place, going from powder form to a plastic encased liquid. Most people probably first heard about this when multiple cases arose of children trying to eat the capsules thinking they were candy.

Within days of being called we were able send out rental screw presses. One firm got a Model CP-4 laboratory press, while the other took one each of two presses, a CP-6 and a KP-10.

It turned out to be a daunting challenge for a screw press. The water soluble (but not soap soluble) skin of the capsules was prone to binding together into a clump. If it did not pass on through the press, it was apt to melt into a mass that would tear open screens and rip flights off their shafts. At the same time we needed to burst open every single one of those capsules. But some, slippery with soap, would slip un-ruptured past the discharge cone.

Huge amounts of reject capsules were generated during the start-up and de-bugging of the soap capsule production lines. At one point we had nine presses rented out, all running around the clock. Several billion pods were run through our machines.

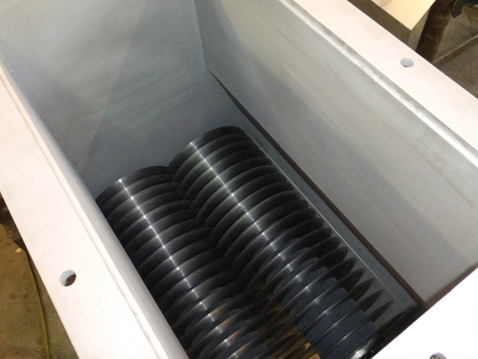

Most recently Vincent has supplied the first Vincent Pillow/Pod Slicer. The VPS-42 is a dual shaft machine designed to slice open sheets, bags, and rolls of soap capsules. Each shaft has its own ten horsepower direct coupled motor. Each shaft has twenty one 10″ meat slicer blades mounted on it. The machine is mounted over the inlet to the screw press. Its successful operation requires that not a single capsule gets through the screw press without being opened.

|

|

|

CONSUMER PRODUCT |

FEED TO SCREW PRESS |

|

|

|

CAKE AND SEPARATED SOAP IN SCREW PRESS |

POD/PILLOWS SLICER |

|

|

|

INLET HOPPER OF POD/PILLOW SLICER |

|