February 4, 2004,

Revised 2008

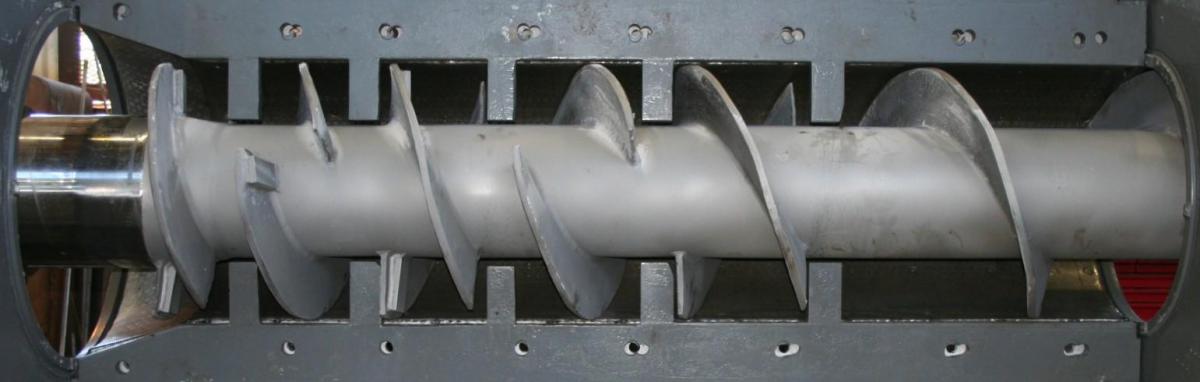

Vincent screw presses feature the interrupted screw design. This is in contrast to most other screw presses, which use the continuous screw design. The interrupted screw design was first invented and patented by Valerius Anderson in the year 1900.

Until that date, the compression screws in screw presses were much like the screw of a screw conveyor. That is, the helicoid flighting started at one end and ended at the other.

What Anderson observed was that, in the continuous flighting arrangement of a compression screw, there are tendencies for slippery materials either to co-rotate with the screw or to pass through with minimal dewatering. He wrote that “brewers’ slops, slaughter-house refuse” and other “soft and mushy” materials dewater poorly in continuous screw presses.

His invention consisted of putting interruptions in the flighting of a compression screw. It was much like having a hanger bearing in a screw conveyor: there is no flighting on the shaft at that point, so material tends to stop moving toward the discharge. It is only after solids accumulate upstream, in sufficient consistency, that the material in the gap is pushed to where downstream flighting catches this material. When this happens, material is forced along its way. The result was better dewatering and a more consistent press cake.

As the years went by, applications of the interrupted screw design were expanded beyond slippery and slimy materials. This took place because competing continuous screw presses worked best only under conditions of constant feed, at constant consistency. If either the consistency or the flow rate diminished, squeezing would diminish until it was inadequate for proper moisture removal. At the same time, if the consistency increased, the press could jam. To counteract these tendencies it was necessary to build a very heavy press, frequently with a variable speed drive which required the attention of an operator.

In contrast, it was found that the interruptions in the flighting of the Anderson screw would provide cushion within the press. If consistency went down, compression was still effective. A plug of sufficiently solid material had to accumulate upstream of each interruption before solids could be pushed towards the discharge. This self-correcting performance prevents wet material from purging at the cake discharge. It is achieved without varying the speed of the screw.

The economic advantages of these characteristics led to interrupted screw presses being used to dewater fibrous materials that are neither slippery nor slimy. Examples would be alfalfa, cornhusk, and, more recently, paper mill fibers.

Following the 1900 patent, a major improvement was made with the addition of resistor teeth. Fitted into the gaps where there is no flighting, these teeth increase the agitation within the press, further diminishing co-rotation tendencies.

Some applications, such as fish and orange peel dewatering, work better if steam is injected into the material being pressed. Resistor teeth provide an economic solution to this need: steam injection holes can be drilled through the teeth so that steam is injected close to the shaft of the screw. Provision for this feature is so simple that it is done at no charge. Vincent provides several presses every year with ports for injection of either steam or CIP solution.

ISSUE #146