ADDENDUM

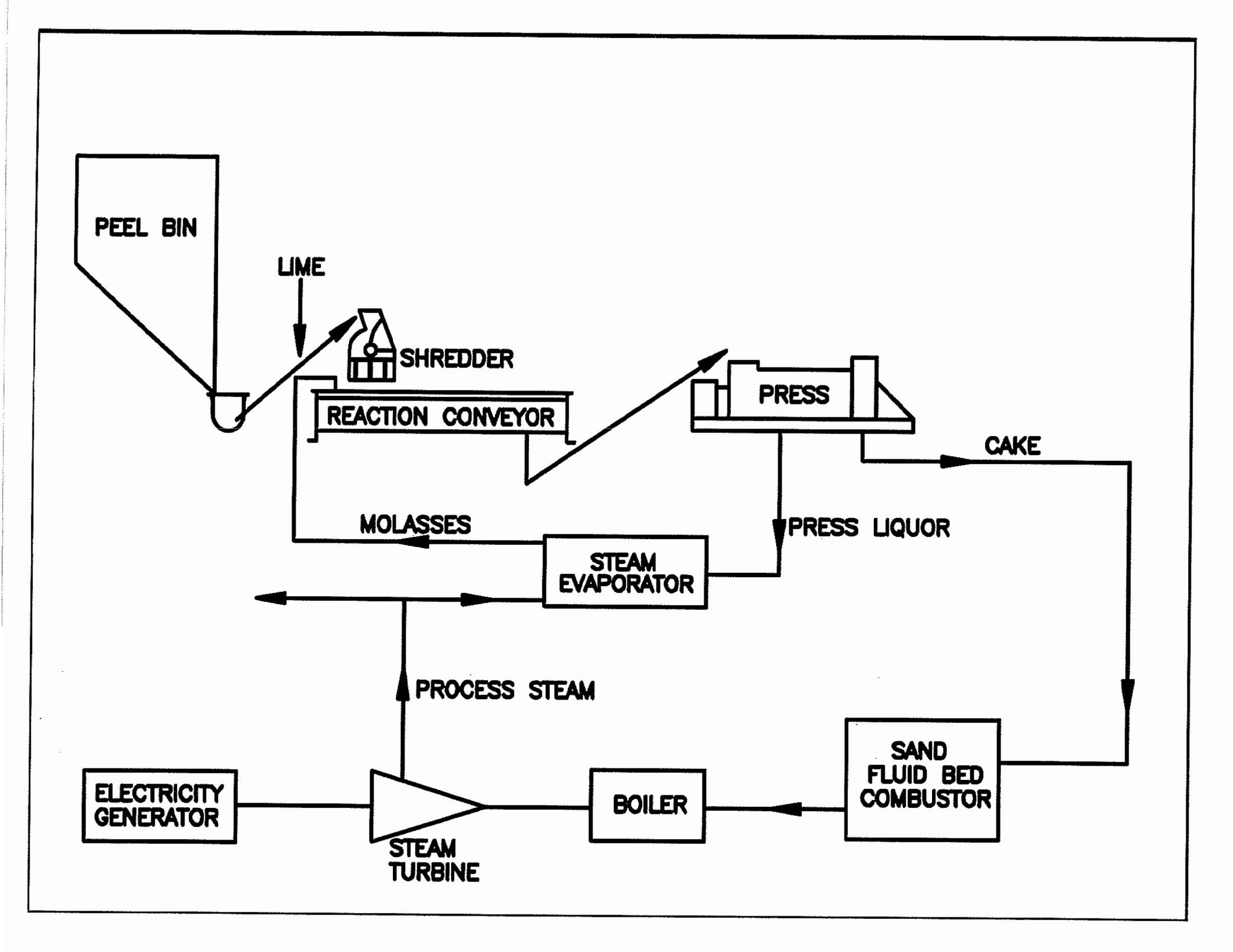

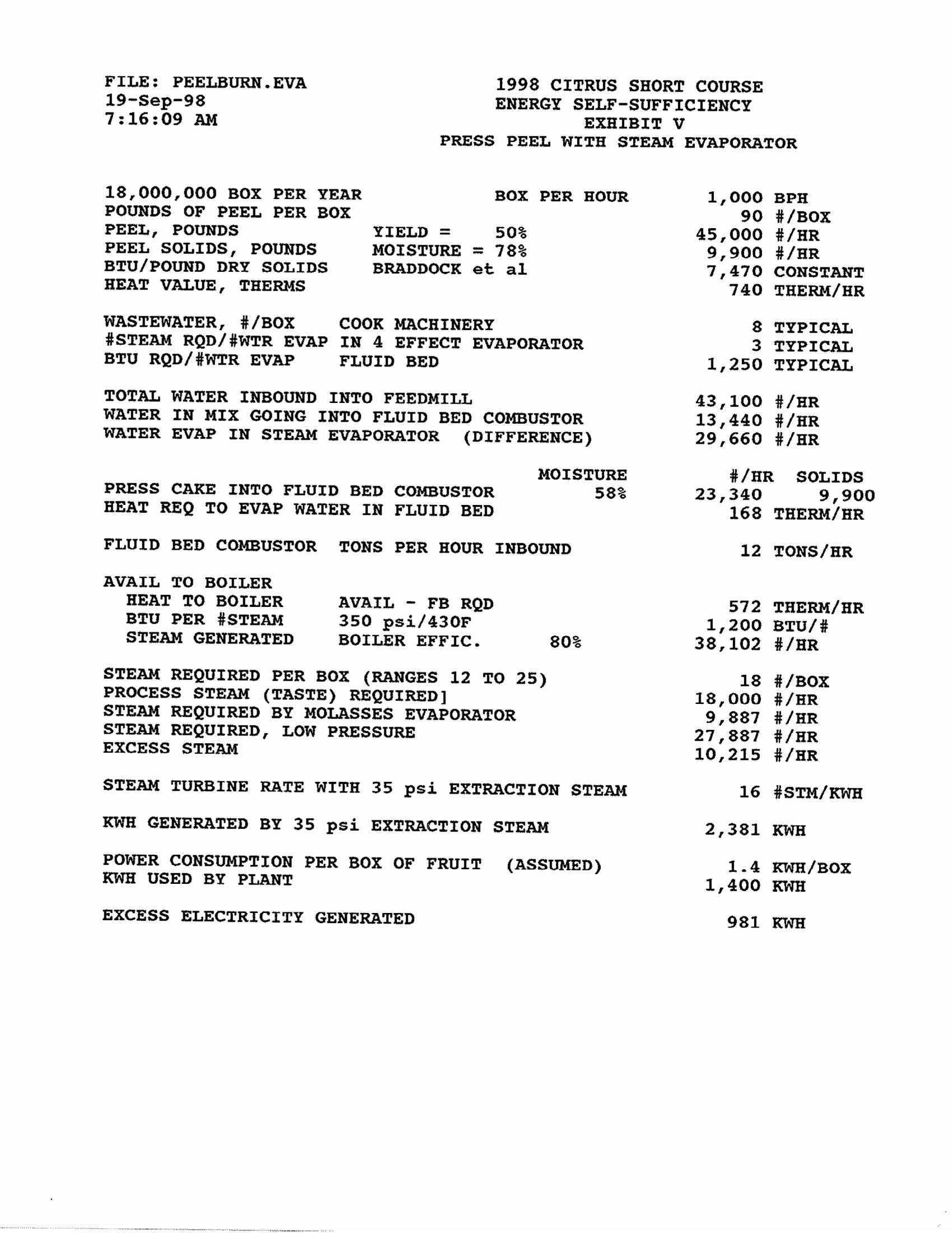

The two processing plant examples used in the September 17 presentation both are based on using existing rotating drum peel dryers. For the greenfield site, there exists a better investment. Instead of installing a dryer, the use of a screw press in combination with a steam driven evaporator is recommended. This will allow a significant improvement in efficiency over the use of a dryer.

With a steam driven evaporator, the press liquor from the screw press can be made into 72º Brix or greater molasses. Diffusing the solids of this molasses into the citrus waste will allow the screw press to produce press cake with a moisture content below 60%. Such press cake can be burned directly in the fluid bed combustor. Blending the press cake with drier material is not required.

In order to minimize capital investment, a four effect steam evaporator has been selected for the calculations in Exhibit V. This evaporator will evaporate approximately three pounds of water for every pound of steam that it uses.

Exhibit V shows that the citrus processor can be entirely energy self-sufficient. A small turbine with 35 psi exhaust steam will be adequate to generate all of the process steam and electricity that is required. There is enough excess steam that the possibility of using an absorption refrigeration system should be considered.

From the standpoint of capital investment, the use of an induction generator is recommended. This is less efficient than alternative equipment; however, it does not require electrical switchgear to synchronize the electric current that is generated.

Addendum II, September 2010

Alex Andreassen of Danisco has pointed out that burning citrus pellets will lead to slagging of the boiler tubes because of the alkali-metals (Na, K) content of the peel. Thus applications would be limited to using pellets as dryer fuel.

Energy Self-sufficiency: Using Citrus Peel as Fuel

September 14, 1998

Summary

A citrus processing plant can be energy self-sufficient. The energy value of citrus waste, when used as a fuel, is sufficient to operate a citrus juicing and concentrating plant. That is, when burned in a steam generator, the BTU value of the peel is sufficient to prepare the peel for burning and to generate the steam required for process needs. With the added efficiency of a waste heat evaporator, there may be enough steam to drive an electric generator to supply the electrical needs of the plant.

Introduction

Escalation of energy costs following the Oil Embargo in 1973 gave rise to theoretical analysis. Was the value of citrus peel greater as an animal feed or as a fuel? A paper by Kesterson, Crandall, and Braddock published in 1979 compared dried citrus pulp with Bunker “c” fuel as a source of energy. It was concluded that the peel was more valuable as a livestock feed.

My personal interest in using peel as a fuel came as a result of looking for alternative uses for citrus waste. The GATT agreements of about four years ago dictate that the tariffs on animal feedstuffs, such as wheat, corn and soy bean meal, will be reduced over the coming years. Since there is no tariff on citrus pellets, the concern was that this would reduce the relative attractiveness of citrus pellets as a dairy feed in Europe. As the great majority of the citrus peel in both Florida and Brasil is pelleted and exported to Europe, the future of the citrus feedmill was being questioned.

The situation came to a head as a result of a dioxin problem in Brazilian pellets. Minute traces of dioxin were found in German and Dutch milk products in April 1998. This was traced to improper fuel oil additives that were burned in some Brazilian orange peel dryers. An embargo went into effect as the citrus processing season was starting. Since the source of the dioxin was not known with certainty, there was urgent interest in disposing of citrus peel by burning. (A directive for individual European nations to control compliance remains in force.)

In Brasil processors such as Citrosuco, Cargill, Cutrale, Dreyfus and Bascitrus have fluid bed combustors that are used for burning sugar cane bagasse. Consequently the option of burning citrus peel in this existing equipment was given serious consideration.

Citrus peel has fuel value because carbon, hydrogen and nitrogen are present in the dry solids. Peel will burn if dried sufficiently. The spontaneous combustion that occurs in citrus pellets and dried pulp give evidence to this fuel value. A quick analysis showed that the energy released is more than enough to dry wet (fresh) peel so that it can be burned.

It was in 1997 that I was introduced to the concept of an energy self-sufficient citrus plant. Gioacchino Sardisco of FMC do Brasil explained that he had studied the matter, with encouraging results. The data that he has supplied for the preparation of this paper have proved invaluable.

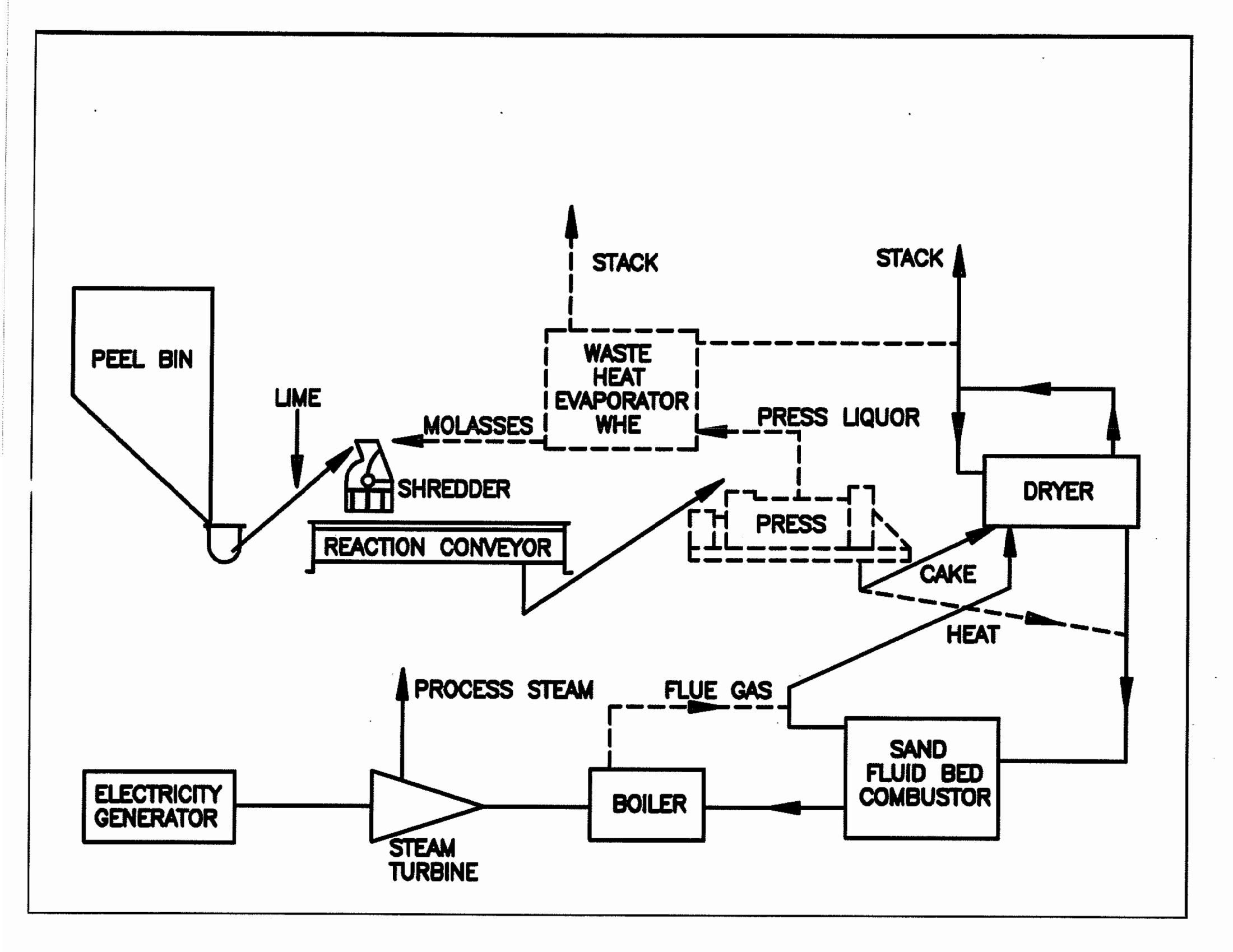

Analysis has shown that it is technically feasible to burn the peel generated by a citrus processing plant. The heat released by this combustion is sufficient to drive the existing feedmill dryers and waste heat evaporators (WHE). Additional heat released in burning the peel is sufficient to satisfy the steam needs of the TASTE evaporators of the processing plant. In fact there is enough additional steam generated that a steam turbine can be used to drive an electric generator. With the proper equipment the electricity generated will be more than enough to fill all of the needs of the citrus processing plant. With such equipment surplus “co-gen” electricity will be available for sale by the citrus processor.

The economic feasibility depends, most of all, on the relative value of dried citrus peel that can be sold as livestock feed, as compared to the cost of energy (fuel and electricity) purchased by the citrus processor. This comparison depends heavily on the relationship between the value of livestock feed and fuel in the country where the processor is located. Clearly the situations in Brasil, the United States, and a Central American country will present three quite different situations.

The capital cost will depend heavily on the existing investment. The cost to convert a US plant with an existing dryer and WHE will be more than required by a Brazilian plant that has these plus the fluid bed combustor with an attached boiler. However, a processor who has been landfilling the citrus waste (but can no longer do so for environmental reasons) faces an entirely different investment analysis.

Discussion

The first step was to find the heat value of citrus peel. This was measured in laboratory studies that were part of Bob Braddock’s 1979 paper. The heat of combustion of dried citrus pulp was found to be 7,470 +/-212 BTU per pound. This figure was very consistent with a variety of measurements made more recently in both Brasil and Florida.

A quick calculation is as follows:

A short ton of pellets typically has 200 pounds of moisture plus 1,800 pounds of dry solids. When burned the solids provide 7,470 x 1,800 = 13,400,000 BTU.

This can be compared to the high thermal value of Bunker “c” fuel oil, 154,000 BTU per US gallon. Based on 10% moisture in the pellets, there are 200 pounds of water which must be evaporated in the combustion process. Using typical citrus peel dryers, this will require about 1,350 BTU per pound of water evaporated, for a total of 200 x 1,350 = 270,000 BTU. Thus, burning a ton of dried peel will release 13,400,000 – 270,000 = 13,130,000 BTU. This is equivalent to about 85 US gallons of heavy fuel oil.

In therms, this is about 131 therms since there are 100,000 BTU’s in a therm. The therm is a unit of measurement used in the calculations for this paper.

In the recent depressed market the value of either 85 gallons of fuel oil or 131 therms of natural gas approached what Florida citrus processors were getting for a ton of pellets. Thus, if a processor had the required combustion equipment, he could have been better off burning his peel than selling it as animal feed!

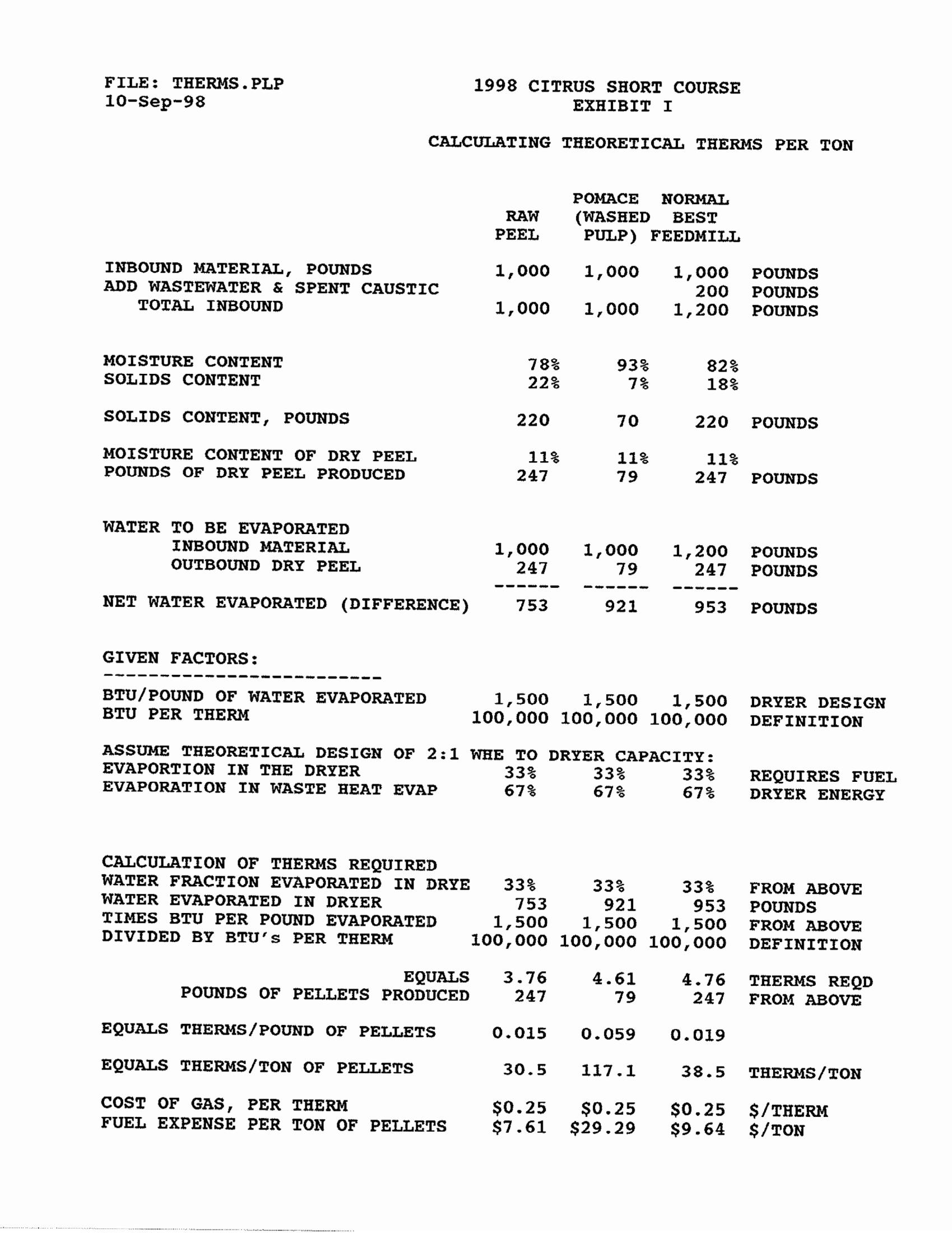

There is another quick analysis that sheds light on the subject. As many of you know, the Florida Citrus Processors Association in Winter Haven has compiled records for many years for their members. These typically show that an average of 50 to 60 therms per short ton are required to produce dried citrus peel (47 was the figure selected for calculations). This would be peel at approximately 10% moisture.

The 50 to 60 therms/ton figure is typical because in Florida both (a) feedmills dispose of (evaporate) large amounts of wastewater along with the peel and (b) most feedmills do not operate with a full 2:1 WHE/dryer ratio. On the other hand, some plants require less than 40 therms per ton. Calculations in Exhibit I show that 38 therms/ton is a realistic optimum figure for drying peel.

In any case, it is apparent that the energy released by burning a ton of dry peel, 131 therms, is considerably more than is required to dry the wet peel. Therefore a citrus processor will have ample peel-fuel to dry all of his wet peel. In fact, the processor will not want to burn all of his peel unless he has a boiler which will make use of the excess energy.

The steam generated by such a boiler can be used to drive the juice evaporators. Typically a citrus concentrate plant uses from 12 to 25 pounds of steam to process a 90 pound box of fruit. (Eighteen pounds were used in preparing this paper, further assuming that a box of oranges yields 45 pounds of peel with 22% solids, with 8 pounds of wastewater being added per box of fruit.)

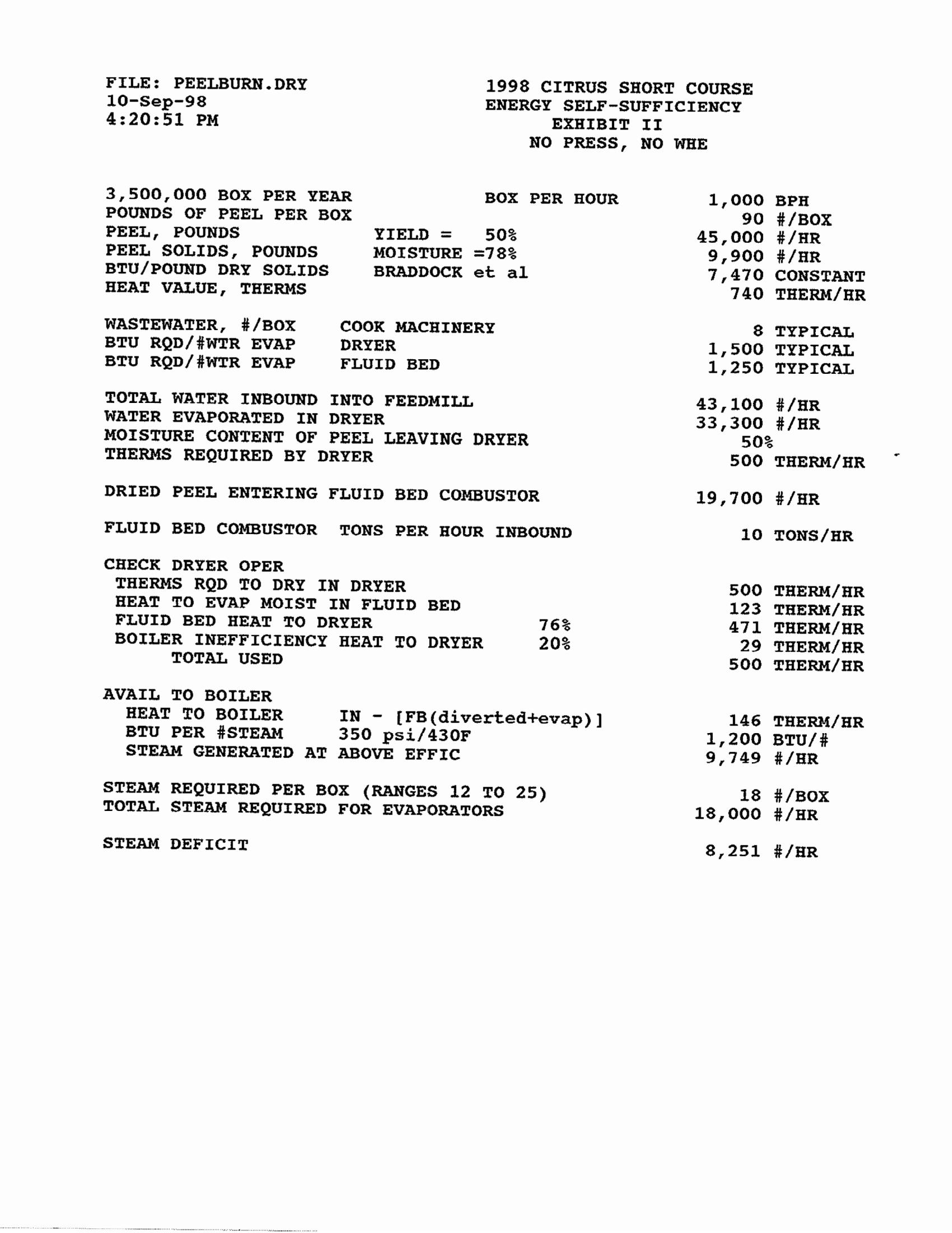

Two mathematical analyses have been prepared. The first, in Exhibit II, is for a small 1,000 box per hour plant. It presumes no peel presses or WHE are available. The reacted peel is fed through the dryer to produce partially dried peel at 50% moisture. This peel is burned in a fluid bed combustor ahead of the boiler.

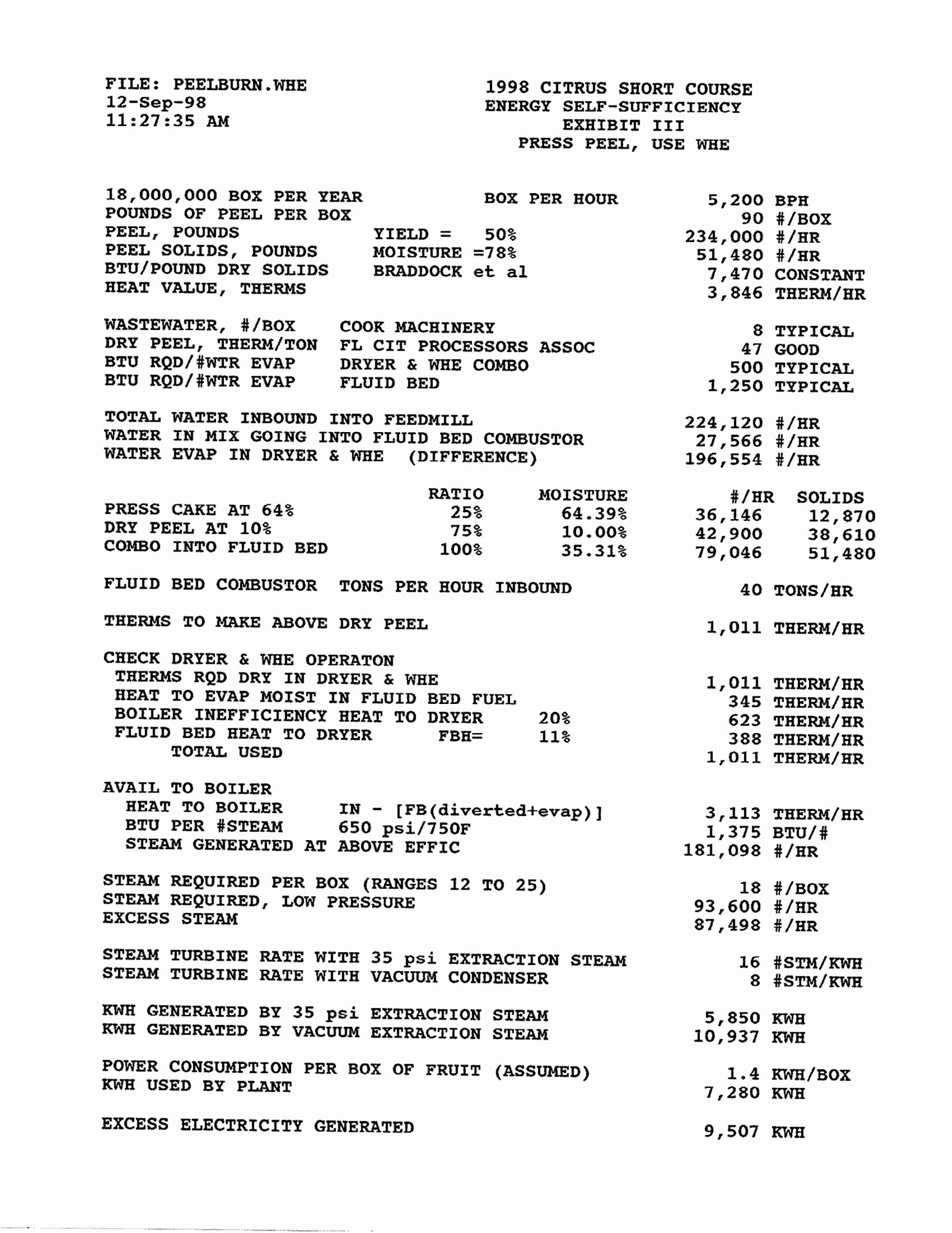

The second analysis, in Exhibit III, has calculations based on a plant that processes 15 million boxes in a season. It assumes there are existing dryers and WHE’s which are used. About three quarters of the press cake is dried to 10% moisture in the dryer. The peel dried in this operation is mixed with the remaining quarter of the press cake that is not placed in the dryer. This combination makes a mixture of peel at 35% moisture, which is what is burned in the fluid bed combustor.

To summarize the figures in Exhibit III: The peel from 15 million boxes provides 3,846 therms per hour of energy. Of this 1,011 therms/hour will be required to dry the peel. This will leave enough heat energy to generate 181,098 pounds per hour of high pressure steam. This steam will be used to generate 16,787 KWH of electricity, well over the 7,280 KWH required to run the plant. 93,600 pounds/hour of the steam will be extracted from the turbine at 35 psi for use in the evaporators, while the rest, 87,498 pounds/hour, will go to a vacuum condenser.

Note that these calculations are based on running only three quarters of the peel through a dryer. The dried peel can be mixed with press cake (or fresh peel) so as to form a mixture with moisture in the range of 25% to 55%. This mixture is then burned in the fluid bed combustor. A material balance is shown in Exhibit IV that supports Exhibit III.

In both examples the flue gasses from the boiler are directed through the dryer so as to assist in drying the peel. Since a WHE operates on high wet bulb temperature gas, and boiler exhaust is normally low wet bulb, close attention to the design is important.

In the small plant shown in Exhibit II with no WHE, all of the energy available in the peel is used to dry the peel and to generate process steam. Excess steam will not be available to generate electricity. If the plant needs to generate its own electricity, supplemental fuel will be required in the fluid bed combustor.

The efficiency arising from the WHE in the larger plant allows use of an electric generator driven by a steam turbine. The turbine is arranged so that both the high pressure injector steam and low pressure process steam are drawn off for use in the evaporators. The rest of the steam would go to a vacuum condenser.

The calculations in Exhibit II and III are very detailed. This was done so that they can be used to calculate alternative scenarios. Besides fitting data to suit a specific processor, the underlying assumptions must be carefully reviewed by fluid bed combustor and boiler experts.

Checking with processors, we have seen examples in which 25,000,000 to 40,000,000 KWH are required to run an equivalent 15 million box plant for a season. The product (FCOJ or NFC) will have a major impact on electricity consumption. Clearly the figures presented herein are only a starting point, not a blueprint.

Burning citrus waste will reduce operating costs. The processing plant will save the money spent on oil or gas. If a WHE is available, additional savings will come from the money spent on electricity. It is even possible to realize incremental revenue from selling electricity. The normal revenue from the sale of citrus pellets (but not all the d- limonene) would be lost, partially offsetting these gains.

What investment is required? It can be examined in steps. As we have seen, a peel reaction system and dryer will be required, while peel presses and a WHE are not necessarily required. The minimum requirement is a fluid bed combustion chamber in which to burn the peel. This alone will reduce the purchased fuel required to operate the dryer. The second step would be to acquire a boiler suitable for use with the fluid bed combustion chamber. This would save the fuel being purchased to run the existing boilers at the citrus plant.

The third step is to acquire the steam turbine, electric generator, and switchgear required to generate steam with the excess peel. This would greatly reduce the electric bill at the citrus plant, plus it can result in revenue from the sale of surplus electricity.

Here is the rough order of magnitude of the investment in an 18,000,000 box per year facility: Two existing 60,000 pound per hour dryers, matched with two existing 100,000 pound per hour WHE’s, represent an equipment cost of about $ 6,000,000. The site work, construction, buildings, utilities and auxiliary equipment (presses, pellet mills, conveyors) probably double this figure to $12,000,000. The addition of a Fluid Bed Combustor, with a 200,000 pound per hour boiler and a 20 megawatt turbine/generator set could be in the range of $20,000,000 to $40,000,000.

The small 1,000 box per hour plant would probably be in the range of $2,000,000 to $5,000,000 depending on options on electricity generation.

Clearly the electricity generating business is more capital intensive than what citrus processors are used to. There is so much capital in an electricity generating plant that it must be run year round. This will require alternative fuels during the off-season. In all likelihood, the business would be financed and operated by a co-gen partnership rather than the citrus processing company.

Burning peel at 10% moisture is very easy. It can be burned clean, with a minimum requirement for excess air, in many kinds of combustion equipment. The soot (ash and unburned fuel in the exhaust gases) will be minimal. However, to burn peel at 50% moisture is more challenging. A fluid bed combustor will be required.

At this point I would like to describe the fluidized bed combustion system. I am deeply indebted to Energy Products of Idaho for this part of my presentation. This company specializes in designing and installing fluidized bed energy systems. They have sold systems in California that have operated with citrus peel in the fuel mixture.

The arrangement they use is called a bubbling fluidized sand bed combustor. The chamber in which the peel is burned can be either rectangular or circular. There is a two foot deep bed of sand on the floor through which the air of combustion enters. The sand and fuel remain suspended in mid-air (fluidized) during operation. The chamber is usually refractory lined, although with some fuels the walls consist of boiler tubes.

With most fuels the burning occurs at 1800º F or less. This is the key to minimizing emissions. A principal emission concern is NOx (nitrogen oxides) which form at higher temperatures. Since citrus peel has 2% nitrogen, this is definitely a design consideration. EPI uses the non- catalytic system for controlling NOx. In severe cases ammonia, at the proper temperature, is added as an abatement agent.

Citrus peel contains around 8% ash, which is greater than the 2% common to sugar cane bagasse. At the same time this is less than the 50% ash that is typical of certain paper mill sludges. In this perspective, the ash in citrus peel becomes manageable.

Ash, in the form of slag, becomes a problem if it comes in contact with hot surfaces. It sticks to hot surfaces, so screening tubes may be used ahead of the boiler superheater. These tubes cool the slag so that it falls into the ash hopper before it has a chance to foul the superheater. In some applications limestone is added because it raises the melting temperature of the ash, reducing the sticky nature of the material. (Limestone also captures sulphur, another contaminant.)

Dioxins and furans are another emission worthy of note. They are grouped with other products of incomplete combustion (PIC’s) such as VOC’s and carbon monoxide. Chlorines give rise to dioxin when incomplete combustion occurs. This occurs when the concentration of carbon monoxide is in excess of 100 ppm.

When burning organic waste on a grate it is not uncommon to find carbon monoxide concentrations in excess of 1,000 ppm. In contrast, the concentration of carbon monoxide in a fluid bed combustor will rarely exceed 50 ppm. Consequently, prevention of the formation of dioxins and furans is possible with fluid bed combustion technology.

The action in the fluid bed combustor is such that auxiliary fuel is not required. That is, peel conveyed or blown in at 50% moisture will dry out and burn without additional heat being supplied by oil or gas burners. However, if additional steam is required, auxiliary fuel can be burned.

The fluid bed combustors being referred to are about 50′ high. Generally they are 20′ wide. The length varies according to capacity. The 18,000,000 box per year plant will have a unit about 45′ long. The footprint, including the boiler and generator, will be about 30′ by 150′.

The fluid bed combustor usually is refractory lined because this helps assure uniform operation despite swings in inbound fuel characteristics. The refractory radiates heat to the peel so as to help evaporate the moisture in the peel. It is noteworthy that some of the sugar cane bagasse burners in Brasil do not use such refractory.

There is one consideration that has a significant effect on overall thermal efficiency. In the process of burning citrus peel all of the moisture must be evaporated. Evaporating this moisture in a fluid bed combustion chamber takes about 1250 BTU per pound of water. On the other hand, the combination of a screw press, dryer and WHE is considerably more efficient: they require only 500 BTU per pound of water evaporation. Thus plants that have existing WHE capacity should use this to its maximum capacity. The practical result is that the peel admitted to the fluid bed combustor will have a lower moisture content and, therefore, will be easier to burn.

The manner in which this works is that the dry peel from the dryer is combined with wet peel (presumably press cake from the peel presses). Some Brazilians have reported the practicality of blending press cake at 67% moisture with some dried peel at 10% to produce a 50% to 55% fuel. (Citrus peel will support combustion with moisture contents as high as 70%.)

The d-limonene in the press cake peel adds fuel value to the peel. It is interesting to note that it causes flashing in the furnace.

One important question arises: How does this relate to the Clean Air Act? Most citrus peel dryer operators in Florida are addressing serious VOC problems. It is thought that evaporation of d-limonene from the press cake in the dryer is a major contributor to the VOC’s being measured. The following scenario should be considered: The oil in the peel going into the fluid bed combustor will be burned and thus cause no VOC problems. Conversely, the oil evaporated in the dryer is a source of VOC’s. Therefore, to minimize VOC’s, it could prove advantageous to dry a minimum fraction of the peel and burn as wet a mixture as practical in the fluid bed combustor.

This analysis assumes that the citrus molasses, which is part of the dried animal feed, is burned. That is, the molasses is either put on the peel going into the dryer or burned directly in the fluid bed combustor. Note that molasses at 50º Brix (50% moisture) has more fuel value than press cake which typically is 62% to 70% moisture.

An interesting alternative would be to sell the citrus molasses separately. This could be of interest to a citrus processor who needs to dispose of all of the peel but does not have a boiler to go with a fluid bed combustor.

Conclusion

This discussion confirms Sardisco’s point: a citrus processing factory can be energy self-sufficient if the peel is burned.

Environmental problems are challenging, but manageable. Even the stringent regulations of the United States can be met.

The future depends on two major forces outside the control of the citrus industry: (1) Where will the market for citrus pellets stabilize in light of dioxin scares and the GATT elimination of the tariff umbrella enjoyed by citrus pellets? (2) Will the declining price of fossil fuels reverse course and go into an upward trend?

In closing let me reiterate that the figures presented here must not be taken as gospel. They are theoretical figures, and they must be modified according to the practicalities of actually burning peel as well as the characteristics of each processing plant.

References and Acknowledgments

- The Heat of Combustion of Dried Citrus Pulp, Journal of Food Process Engineering 3 (1979) 1-5, by J. W. Kesterson, P. G. Crandall, and R. J. Braddock.

- Sugar Cane Bagasse: An Alternate Fuel in the Brazilian Citrus Industry, Food Technology, May 1988, by Jose Luiz Guerra and Elizabeth Steiger.

Invaluable and important assistance in the preparation of this report was given by:

- Ralph Cook of Cook Machinery, Dunedin, Florida (727-796-1367)

- Kent Pope of Energy Products of Idaho, Coeur d’Alene, Idaho (208-765-1611)

- Gioacchino Sardisco, FMC FoodTech, Araraquara, Brasil, (011- 55-16-232-1300)